Rev. 11/18/2019

LAD-EZ (6-12 STEPS), MANUAL

Copyright 2019 Vestil Manufacturing Co.

Page 19 of 20

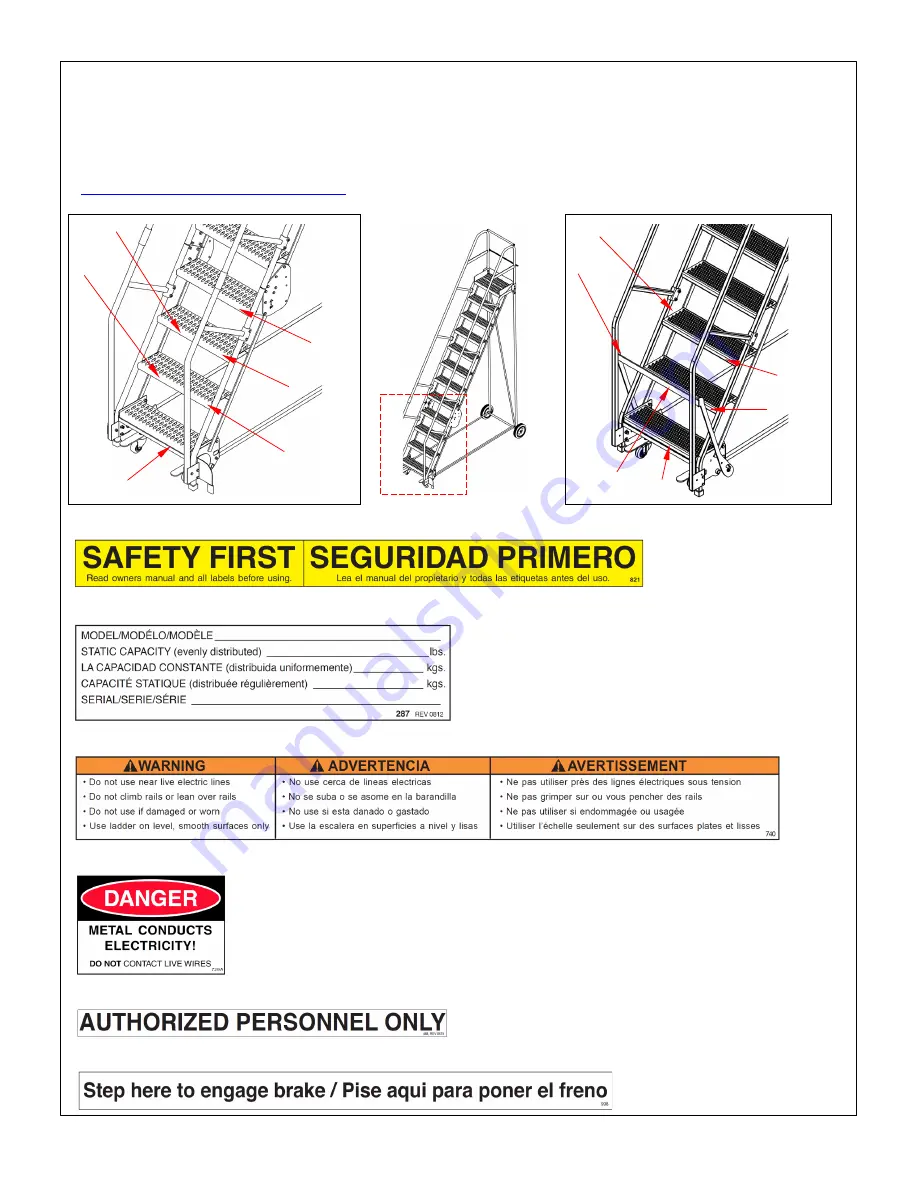

LABELING DIAGRAM

Each unit should be labeled as shown in the diagram. Label content and location are subject to change so your

product might not be labeled exactly as shown. Compare the diagram below to your

. If there are any differences between actual labeling and this diagram, contact

Replace all labels that are damaged, missing, or not easily readable (e.g. faded). To order replacement labels

or to inquire whether your unit is properly labeled, contact the technical service and parts department online at

http://www.vestilmfg.com/parts_info.htm

or by calling (260) 665-7586 and asking for the Parts Department.

D: Label 729

A: Label 821

B: Label 287

E: Label 468

C: Label 740

A

B

C

D

E

F

A

E

B

C

F

D

Ladders

with gate

option

F: Label 998