Vertiv™ XTE 802G Generator Room Walk-In-Cabinet Description and Installation Manual

45

8

Sealing Cable Entries and Openings with Factory Cover-

Plates

8.1

General

In keeping with best industry practices, seal all cable grommets penetrations against weather, rodent and insect intrusions.

It is extremely important to maintain a well-sealed XTE 802G. Failure to do so can jeopardize the enclosed electronic equipment, as

well as the proper functioning of the XTE 802G systems. All cable transitions into the XTE 802G must be properly sealed as required.

Refer to the following procedure to seal cable entries with duct sealing foam:

1.

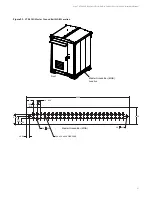

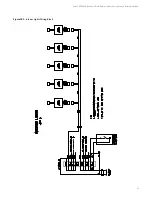

Route the cables into the XTE 802G through bottom-entry conduits (preferred) or through side-entry conduits in the XTE

802G base structure (if absolutely necessary). The bottom-entry and removable side-entry plates have pre-configured

knockout stampings to facilitate conduit connections.

2.

Route the OSP cables into the XTE 802G by removing a Roxtec port frame from the finished floor inside the XTE 802G. Use

a fiberglass fish tape from a side-entry port to extend to below the Roxtec port. Reach down through the finished floor to the

fish tape, and use it to route pull cord or cables as required. Conduit knockouts are directly below each Roxtec port in the

XTE 802G base pan.

3.

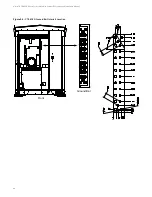

Route OSP cables to equipment through the Roxtec port frame, securing to cable rack and equipment frames as required.

4.

Seal all conduit openings with Roxtec blocks, duct sealing foam or the equivalent against weather, animal and insect intrusion

into the XTE 802G.

5.

Replace port covers, Roxtec port frames and any other material removed during installation.

6.

Verify that cables are routed as required and that all cable entries are properly sealed.

8.2

Generator Installation

After installation of a generator in this enclosure, it is the end-user’s responsibility to seal the enclosure to maintain the rain-proof

rating.