English

(translation)

4

10.2017

60205045

10. Bearings and lubrication

The roller bearings of the motors in standard confi gurati-

on are lubricated by the bearing manufacturer (or at the

factory) using roller bearing grease in accordance with

DIN 51825 as shown in the following table:

At full capacity, the lubricant quality permits running

the motor for approximately 10000 operating hours for

2-pole confi gurations and 20000 operating hours for

multi-pole confi gurations without replacing the roller

bearing lubricant, unless agreed otherwise. The speci-

fi ed number of operating hours only applies to operation

at nominal rotational speed.

11. Draining Condensate (optional)

At sites where condensation and the formation of

condensate inside the motor must be expected, the

accumulated condensate needs to be drained at regular

intervals using the condensate drainage opening at the

lowest point of the bearing shield; when done, the open-

ing must be closed again.

12. Cleaning

To ensure the effectiveness of the air cooling, all parts

of the motor need to be cleaned regularly. Usually,

cleaning with compressed air (water-free and oil free)

is suffi cient. In particular the ventilation openings and

spaces between the fi ns need to be kept clean. It is rec-

ommended to include the electric motors in the regular

inspections of the driven machine.

13. Motors with PTC resistors (TPM)

Continuity testing of the PTC resistor sensor circuit with

test lamp, magneto or similar is strictly prohibited, since

this would lead to the immediate destruction of the sen-

sor. If an additional measurement of the cold resistance

(at approx. 20°C) of the sensor circuit is necessary,

the measurement voltage may not exceed 2.5 V DC.

It is recommended that the measurement be carried

out using a Wheatstone bridge with a supply voltage of

4.5 V DC. The cold resistance of the sensor circuit may

not exceed 810 Ω. A measurement of hot resistance is

not required. For motors with thermal coil protection,

precautions need to be taken to ensure that after the

thermal coil protection has responded and after the mo-

tor has cooled down, an unintentional automatic restart

will not cause any danger.

14. Warranty, repair, spare parts

Our authorised repair shops are responsible for repairs

under warranty, unless expressly agreed otherwise.

They can also perform any other repair work that may

become necessary in a professional manner. For infor-

mation about how our customer service works, please

contact the factory. Proper maintenance as specifi ed in

the Maintenance section does not count as tampering

under the terms of the warranty. It therefore does not

release the factory from its agreed obligations under the

warranty.

15. Electromagnetic compatibility

The compliance of the motors as dependent compo-

nents with the EMC standards has been verifi ed. The

system operator is responsible for ensuring by means of

suitable measures that devices or entire systems meet

the relevant electromagnetic compatibility standards.

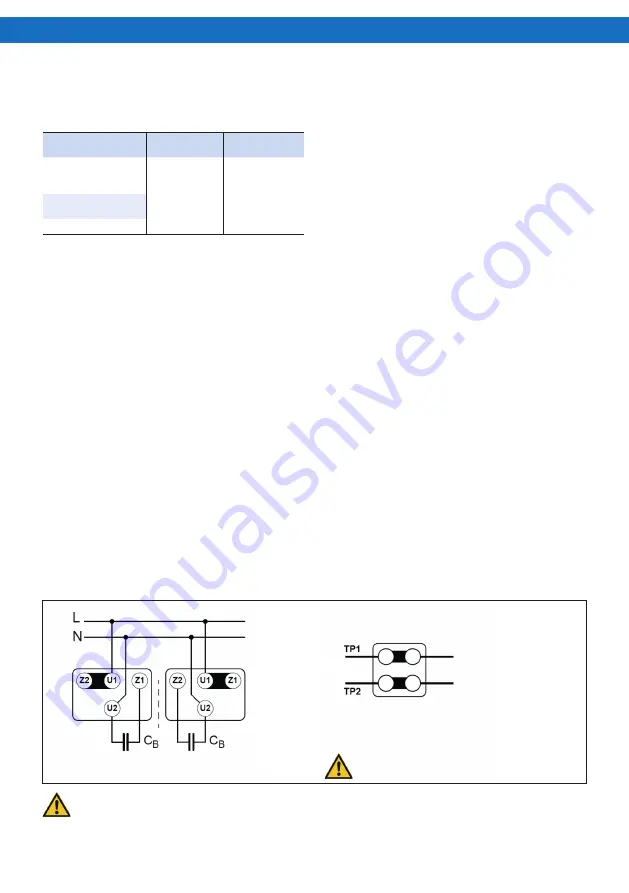

16. Terminal socket connections

(standard confi guration):

Connection of tripping unit:

done according to the connection diagram

of the tripping unit.

Do not apply voltages greater than 2.5 V!

Motor with PTC resistor:

(terminal socket connection as shown on the left)

Counter-clockwise

Clockwise

Check that all terminal connections are fi rmly seated before putting the machine into operation!

From

motor

Type series

Lubricating

grease

Lubricating

grease base

Squirrel-cage motors

IEC/DIN 56 – 132T and

Transnorm 56 – 100

Asonic GLY 32

or

Multemp SRL

Lithium soap

Motors with separate

fans

Brake motors

English

(translation)