4

VEGAMET 841, 842, 861, 862

61274-EN-191219

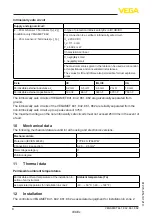

Ambient temperature

You can find the details in chapter "

Thermal data

" of these safety instructions.

Electrostatic charging (ESD)

You can find the details in chapter "

Electrostatic charging (ESD)

" of these safety instructions.

Zone 2 applications

T

he device must be installed in a protective housing or a switching cabinet with IP54 according to

IEC 60079-0.

The device may only be used in an area with a minimum pollution level of 2 or better, as defined in

IEC 60664-1.

6

Safe operating mode

General operating conditions

•

Do not operate the instrument outside the electrical, thermal and mechanical specifications of

the manufacturer

Connection conditions

•

The connection cable of VEGAMET 841, 842, 861, 862 has to be wired fix and in such a way

that damages can be excluded

•

If the temperature at the inlet components exceeds 70 °C, temperature-resistant connection

cables must be used

7

Important information for mounting and maintenance

General instructions

The following requirements must be fulfilled for mounting, electrical installation, setup and mainte

-

nance of the instrument:

•

The staff must be qualified according the respective tasks

•

The staff must be trained in explosion protection

•

The staff must be familiar with the respectively valid regulations, e.g. planning and installation

acc. to IEC 60079-14

•

Make sure when working on the instrument (mounting, installation, maintenance) that there is no

explosive atmosphere present, the supply circuits should be voltage-free, if possible.

•

The instrument has to be mounted according to the manufacturer specifications, the Certificate

of Conformity and the valid regulations and standards

•

Modifications on the instrument can influence the explosion protection and hence the safety

•

Modifications must only be carried out by employees authorized by VEGA company

•

Use only approved spare parts

•

Components for installation and connection not included in the approval documents are only

permitted if these correspond technically to the latest standard mentioned on the cover sheet.

They must be suitable for the application conditions and have a separate certificate. The special

conditions of the components must be noted and if necessary, the components must be inte

-

grated in the type test. This applies also to the components already mentioned in the technical

description.

Mounting

Keep in mind for instrument mounting

•

Mechanical damage on the instrument must be avoided

•

Mechanical friction must be avoided

IECEx

Содержание ATEX

Страница 40: ...38 Notes VEGAMET 841 842 861 862 Installation in Zone 2 61274 01 191219 ATEX...

Страница 41: ...39 Notes VEGAMET 841 842 861 862 Installation in Zone 2 61274 01 191219 ATEX...

Страница 52: ...10 Notes VEGAMET 841 842 861 862 61274 EN 191219 IECEx...

Страница 53: ...11 Notes VEGAMET 841 842 861 862 61274 EN 191219 IECEx...

Страница 64: ...10 VEGAMET 841 842 861 862 61274 EN 200723 13 Installation diagram c UL us...

Страница 65: ...11 VEGAMET 841 842 861 862 61274 EN 200723 c UL us...

Страница 67: ...ATEX IECEx cULus VEGAMET 841 842 861 862...