Wiring Schematics

VaporTEK Wiring

31

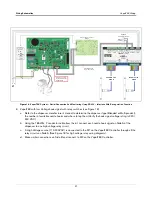

Figure 18.

VaporTEK System – Serial Connection And Monitoring Using RS422 – Interface With Re-regulation Function.

6.

VaporTEK with low Voltage hook signal with relay switches (see Figure 16)

a.

Refer to the dispenser manufacturer’s manual to determine the dispenser type (Blended or Multi-product),

the number of available nozzle hooks and where to tap them (Verify the hook signal voltage rating is 220/

240 VAC).

b.

Using the 18AWG, 2 conductor cable from the kit, connect each nozzle hook signal on Side A of the

dispenser to one high voltage relay circuit.

c.

A High Voltage source (110-230VAC) is connected to the M1 on the VaporTEK Controller through all the

relay circuits on Side A (See Figure 18 for high voltage relay wiring diagrams).

d.

Make similar connections on Side B and connect to M2 on the VaporTEK Controller.

-B+ -A+

Pulse

Out B

-2 + -1+ - +

Out A

5 V

B A

B

A

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

PE N L

RS485

230 V~

RS485-4

- 2+ -1+

FAFNIR

VAPORIX - Control

S

ervice

VAPORIX Flow -

SIDE A

VEEDER-ROOT

VAPORTEK-CONTROLLER

900890-001

Rev

.C

P/N 141 031 916

S/N 0000586

D

A

TE 49/2016

RoHS Compliant

PE

F1

PE

L

N

PE

M1

M2

+ - AB SB AA SA

EPV V

A

LV

E

MOTOR

POWER

MOTOR

SIGNAL

J3

V6

V3

V8

V1

X7

X6

X8

PROGRAM

J1

J2

X3

X2

X1

X4

BR1

IC5

RS422

UNSAFE AREA

UNSAFE AREA

SAFE AREA

L1

N

MAIN

230V

L1 N PE

M1 M2

PULS

Power Supply

100W

140 810 856

24V

DC

OK

L

N

+ +

VAPORIX Flow -

SIDE B

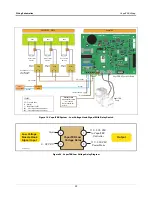

VRC RS422

P6015

P6001 PSU

AND BBM

E101 CPU

RS485

Interface

Standard RS422

10-pin ribbon cable

Gilbarco CPU Board E101

M06104

Optional

Kiosk Alarm Indicator

Jumpers J1 and J2

are not used in this

configuration.