Testing Procedures

Manifolded Pumps with Leak Detectors

15

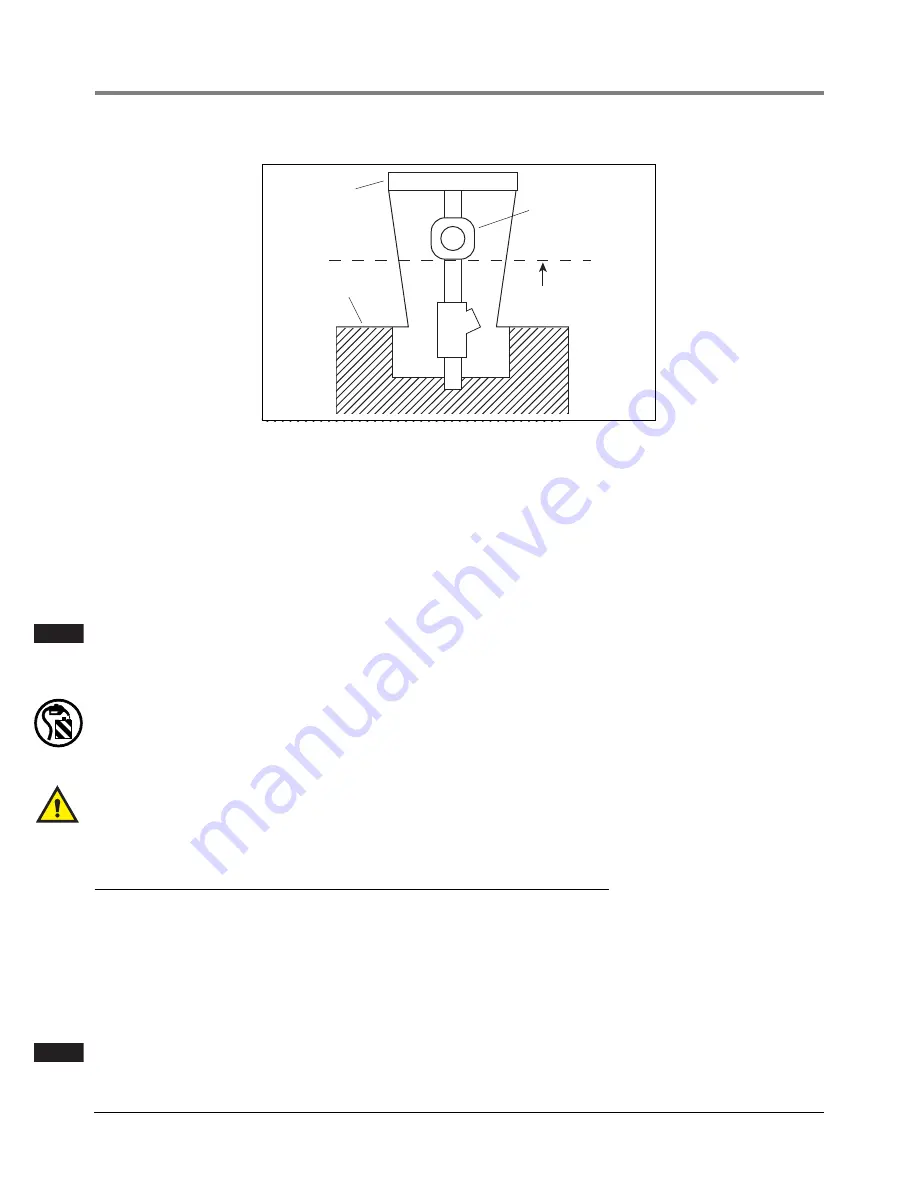

Figure 6. Discharge fluid height limit example

By raising the discharge point of the simulated leak from the FXT above the test area, additional static head is

placed on the LLD. Static head is defined as the pressure exerted on the LLD by the vertical column of fluid

contained within the piping, from the LLD upward to the point of discharge of the leak. By placing the point of

discharge high enough above the island, sufficient static head pressure could be placed upon the LLD to keep

it from entering the leak sensing position. It is assumed that piping from the LLD to the point of discharge is a

continual, gradual, upward or positive run and does not have a negative (declining) run.

For more information on static head effects, please see Red Jacket Service Bulletin 23-5 and 23-18 or the ap-

plication section of the mechanical leak detector manual covering the effects of static head on mechanical leak

detectors.

If the LLD or pumping system operation differs significantly from that described in this manual,

see leak detector manual #5191 and/or Petroleum Products Service Manual #5190, for possible

causes and solutions.

3.

Plug the FXT into the Snap-Tap on the dispenser shear valve as shown in Figure 5 on page 14.

CAUTION! To avoid product spillage, assure the discharge is directed into a suitable container.

4.

A leak check may now be performed by following “Simulated Leak Test - 4 Step Test” on page 7. In this case,

product is not being returned directly to the tank via the Snap-Tap fitting on the pump but is collected in the

container.

Snap Tap connectors shall not be left permanently installed into the impact/shear valves and must be

removed upon completion of testing.

Manifolded Pumps with Leak Detectors

For manifolded systems that have two LLDs on a single line and the pumps operate simultaneously, testing must

be performed at the impact valve, as shown in Figure 5.

The minimum leak detectable will be the sum of the two LLD’s capabilities; typically 6 - 7 gph at 10 psi (23-26 lph

at 69 kPa).

If the minimum leak detectable is unacceptable, the LLDs may be tested individually by having only one pump

come on during the test. This will help in determining which LLD is causing the unacceptable rate.

Pumps must be activated simultaneously in manifolded systems. If they alternate, LLDs cannot be

accurately tested.

Dispenser

Grade

Solenoid

Do not discharge

fluid above this line

rj\fxt1.eps

NOTE

G

A

S

NOTE