184

Vehicle care

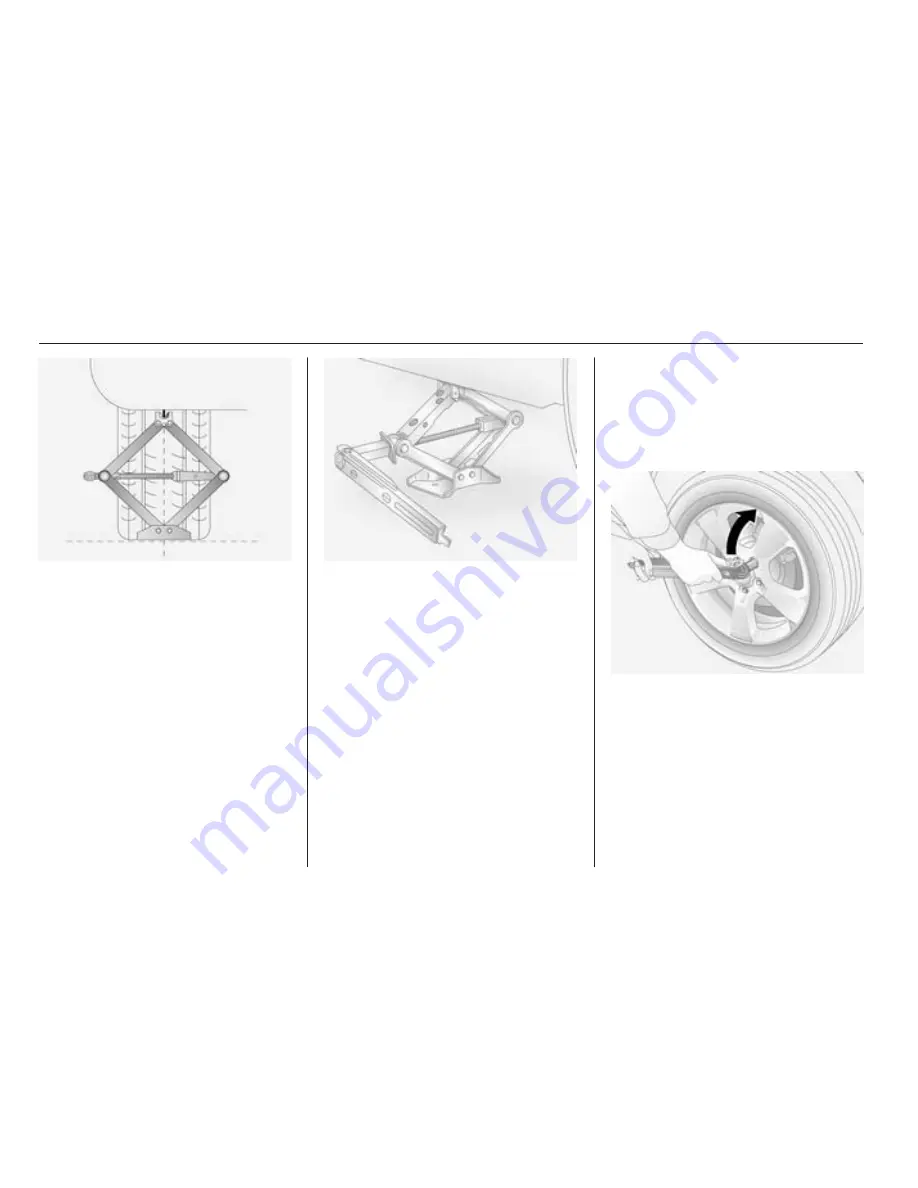

4. Before positioning the jack, set it

to the necessary height by

rotating the eye by hand.

Position jack at the jacking point

located nearest to the wheel

concerned so that the jack claw

spans the vertical base. Ensure

the jack is positioned correctly.

The jack base must be on the

ground directly below the jacking

point in a manner that prevents it

from slipping.

5. Attach wheel wrench to eye of

threaded rod and rotate wrench

clockwise to raise vehicle.

If this is not the case, carefully

lower the vehicle immediately and

reposition the jack. Raise the

vehicle until the wheel is just clear

of the ground.

6. Unscrew wheel nuts completely

and wipe clean with a cloth.

Do not grease the threads. Put

wheel nuts somewhere where the

threads will not be soiled.

7. Change the wheel. Notes on

spare wheel

3

185.

8. Screw on the wheel nuts and

tighten slightly by hand by turning

clockwise until wheel is held

against the hub.

9. Rotate wrench anticlockwise and

lower vehicle to the ground.

10. Install the wheel wrench ensuring

that it locates securely and tighten

each wheel nut in a crosswise

sequence. Tightening torque is

140 Nm.

11. Stow the replaced wheel

3

185

and the vehicle tools

3

173.

12. Check the tyre pressure of the

installed tyre as soon as possible.

Содержание Antara 2014

Страница 3: ...2 Introduction Introduction ...

Страница 6: ...Introduction 5 ...

Страница 11: ...10 In brief Instrument panel overview ...

Страница 83: ...82 Instruments and controls Control indicators in the instrument cluster ...

Страница 122: ...Climate control 121 Cleaning of condenser and evaporator drainage Performance check ...

Страница 169: ...168 Vehicle care ...

Страница 172: ...Vehicle care 171 ...