CB-800

CB-1000

2.3.1.1 T

ECHNICAL

D

ATA

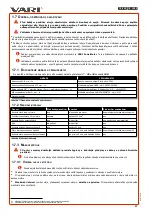

Description

Unit

CB-800

CB-1000

Length x width x height (including the handlebars in the middle position)

mm

1,640 x 1,005 x 1,175

Weight

kg

70

73

Machine's maximum working width / brush diameter

mm / mm

800 / 370

1000/370

Safe slope operation

10°

Travel speed

km.h

-1

2,78 ; 3,53

Machine's surface output

m

2

.h

-1

2219 ; 2825

2773 ; 3,531

Volume and grade of oil filling in the travel gearbox

l (litre)

API / SAE

0.04

GL-5 / 90H

Volume and grade of oil filling in the drive gearbox

l (litre)

API / SAE

0.125

GL-5 / 90H

Table 15: Technical data CB-800 /CB-1000

2.3.1.2 E

NGINE

I

NFORMATION

Any additional information about the engine

not stated

here is available at the engine manufacturer’s website.

Engine

Unit

CB-800

CB-1000

Type

-

HONDA GCVx170 N2EWSD

Maximum (set) engine speed

min

-1

3,200

±

100

Maximum (short term

) engine tilting

20° / 30°

Fuel tank capacity

l (litre)

0.91

Fuel

petrol

Oct. No. 91-95

Engine oil filling

l (litre)

0.4

Oil grade

SAE / API

Summer operation: SAE 30 / SJ or SH

Winter operation: SAE 0W-30 / SJ or SH

Table 16: Basic details of the engine

2.3.2 D

ESCRIPTION

OF

THE

MACHINE

AND

ITS

PARTS

1

Machine frame

6

Left wheel

11

Front cover

16

Fuel tank cap

2

Handlebars with control levers

7

Right wheel

12

Rear cover

17

Oil dipstick

3

Engine

8

Brush rotation lever

13

Fenders

18

Air filter

4

Support wheel

9

Pressure adjustment control

knob

14

Handlebar clamp nut

19

Exhaust silencer

5

Brushes

10

Guide rails for accessories

15

Starter

Table 17: Legend to Fig. 1

2.4 O

PERATING

I

NSTRUCTIONS

2.4.1 G

RIPPING

POINTS

•

The gripping points for manual lifting are marked with the hand symbol -

Fig. 2

B

:

at the rear of the machine, tubular handlebar holder

at the front of the machine beam in the engine plate

2.4.2 M

ACHINE

TRANSPORT

When transporting the machine in a car or other road vehicle, always secure the machine against any unexpected

movement with certified lashing straps.

•

Always flip and lock the handlebars in the transport and parking position - see

Chap.2.4.3.1 Handlebar adjustment

on page

.

•

Always place the machine with its front end (= brushes) in or across the direction of travel of the vehicle.

•

The binding points are (straps are shown by thick lines in

Fig. 2

B

:):

at the rear of the machine, tubular handlebar holder

at the front of the machine support wheel

eye on the left on the engine plate

46

When the sweeping rollers are set to the middle position, when the machine's sweeping stroke is maximised as shown in the table.

47

For more information about the engine, including the spare parts numbers, go to

www.honda-engines-eu.com

48

Engine type designation may change. Please refer to the engine block for the current engine type specification designation.

49

Short term - up to one minute.

50

Measured per new standard

Society of Automotive Engineers (SAE) J 349

51

With regard to the ever increasing ratio of BIO-components in fuel, use fuel stabilizer.

26

re

vi

ze

1

2/

20

21