Programming the InFusion Controller

All programming is created in InFusion Design Center

software. Projects should be saved regularly when being

created. They may be edited at any time in Design Center and

resaved (preferably under a new name). Design Center

projects may also be saved to MMC/SD flash memory cards.

The card can then be placed into the card slot reader in the

front of the InFusion Controller to program the IC (see

Front

Buttons

below). Design Center projects may be downloaded to

the IC via Ethernet or USB.

Memory Card

An MMC/SD flash card slot is provided for program backup.

•

Stores all programming for project file

•

Stores graphic rich web interface (future feature)

•

Can be read and written directly using Design Center

Diagnostics.

•

InFusion System (all Controllers) may be

programmed/re-programmed from the flash card

connected to any Controller without running Design

Center or connecting a computer.

•

Only one flash card is needed and only one is

recommended per system

•

See Design Center software Help for details

Controller Bus to Controller Bus Wiring

When connecting multiple Main Enclosures, Vantage

recommends the use of 16-18 AWG 2-conductor, twisted pair,

non-shielded wire from IC to IC.

This is a polarized connection

with “+” and “–“ screw terminals for two runs of wire. The

beginning and ending Main Enclosures will use one set of

screw terminals at the Controller Bus terminals and all Main

Enclosures in-between will use both sets of screw terminals on

the Controller Bus terminals, i.e., one set of screws connecting

from the previous enclosure and the other set of screws

continuing to the next enclosure. The maximum wire length for

all Controllers connected together on one bus should not

exceed 2,000ft. using the above wire specification.

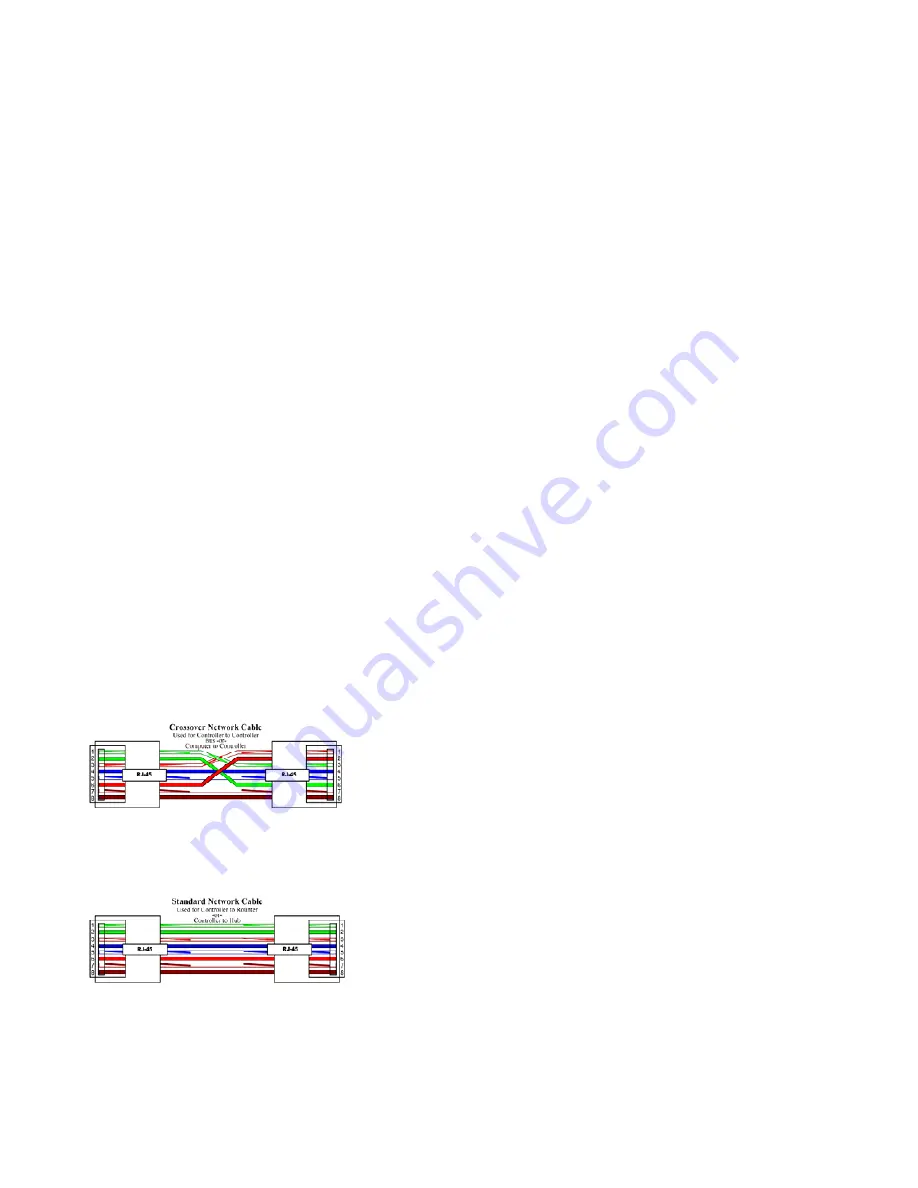

Controller to Controller Ethernet Wiring

InFusion Controllers may also be connected using the Ethernet

ports on the front of each Controller. When this is done a

cross-over network cable must be used from controller to

controller. The maximum length of a crossover network cable

is 328ft or 100meters. C2C, Ethernet connection must be

Enabled

– see

InFusion Controller Front Panel Button

Operation

(below).

Controllers may also be connected using a standard network

cable to a router or hub. With this type of connection it may be

necessary to assign unique Channels from IC’s front panel, in

case more than one InFusion Design Center System is on a

network. With this type of connection InFusion network

distances are only limited to the network itself.

Controller Terminator Switch

If only one DIN InFusion Controller is used, the

Controller

Network Termination

switch should be ON. This switch is

located on the front/top side of the Controller. If multiple

Controllers are used ONLY the first and last Controller on each

Controller Network Bus should have the

Controller Network

Termination

switch ON.

Example 1:

In a five Controller system, Controllers 1 and 5 are

not necessarily the first and last Controllers, i.e., the “wiring”

order could be 2-1-3-5-4. In this example, Controllers 2 and 4

are the first and last Controllers in the network, so only these

two would have the

Controller Network Termination

switch

ON, the other three must be OFF.

Example 2:

In a ten Controller system, let’s say enclosures 1

through 5 are connected through one Controller Bus and

enclosures 6 through 10 are connected through another

Controller Bus. Each of these independent Controller Buses

could have up to 2,000ft of cabling. Controllers 5 and 6 are

connected through Ethernet. In this example enclosures 1 and

5 are terminated for the first Controller Bus and enclosures 6

and 10 are terminated for the second Controller Bus. This is

because they are two independent Controller Bus networks,

connected together with one Ethernet connection. This

scenario may be repeated multiple times in various

configurations up to 31 Controllers maximum on one system.

Auxiliary Power

On the bottom of the IC-DIN are connectors for a 12VDC

auxiliary power connection. Connect the common to any GND

on the bottom of the Controller. The 12VDC connection is

typically used for

one

RF Enabler. Total power is limited to

250ma. NOTE: If an additional RF Enabler is connected to the

DIN Controller, it must be powered externally.

RS-232 Connections

The IC-DIN has five RS-232 ports. These ports may be used to

connect any device that uses RS-232 communication. Any

compatible RS-232 device may be connected, however, only

one device should be connected at a time to any RS-232 port.

The default protocol may be changed through Design Center

software.

Most devices typically use RX, TX and GND for communication.

In the event that an RS-232 device requires RTS and CTS use

Port 1 or Port 2. RS-232 Ports 3-5 only have TX, RX and GND.

All five ports can use software flow control

.

Communication protocol settings:

•

Standard baud rates 1200 – 115.2K

•

7-8 Data Bits

•

Even, Odd, Forced or No Parity

•

100ft. maximum wiring distance

RS-485 Connections

On the top connector of the IC-DIN are two RS-485 ports. The

RS-485 ports are

half-duplex

, meaning that each port can

transmit and receive but not at the same time. Maximum wiring

distance for RS-485 ports is 200ft.

Front Buttons

Through the front panel buttons on the DIN InFusion

Controller, Time, Connection protocol, IC Information,

Controller Address and other settings may be edited. The

Controller may also be placed in boot (Redboot) mode from

the front controls. The following contains detailed information

for some of the LCD screens shown below:

SCREEN 4 – A static IP address may be assigned to the IC.

Once a static IP address has been assigned to the Controller

and saved, the NM: (NetMask) address displays automatically.

A typical NetMask would be 255.255.255.000. With the

NetMask field highlighted click the Adj. button to change to

GW/GateWay, and adjust the Gateway address.

SCREEN 6 – This screen allows the InFusion Controller to

obtain an IP address automatically through DHCP. Record this

address in the Design Center project file for future connections

through Ethernet.

SCREEN 7 – This screen shows information about the IC.

•

Uptime

– the amount of time the IC has been operating

without loosing power, reported in

days:hours:minutes

.

•

RAM

– Free Memory / Total Memory

o

RAM is like the RAM on a computer. This is the active

memory, Random Access Memory and is volatile,

meaning when power is lost to the Controller, this

memory is cleared.