5.2.4 ROTOR DRIVE

5.2.4.1 BELTS TIGHTENING

When the rotor drive is engaged, an idler pulley is

moved into position to tighten the belts and transmit

power. As the belts wear and stretche, it will be nec-

essary to adjust the turnbuckle to maintain proper

tension. To set belts tension, follow this procedure:

1. Clear the area of bystanders, especially small

children.

2. Stop engine, shut off fuel supply lever, remove

ignition key (electric models only), disengage all

drives and wait for all moving parts to stop.

3. Engage the rotor drive control.

4. Check the tension of the belts by applying a

small force to the center of the belt span. It can

deflect 1/2 to 1 inch (12 to 25 mm) in either direc-

tion.

5. If the belt deflection is greater than 1 inch (25

mm) or the drive slips during operation, the idler

should be adjusted to provide more movement.

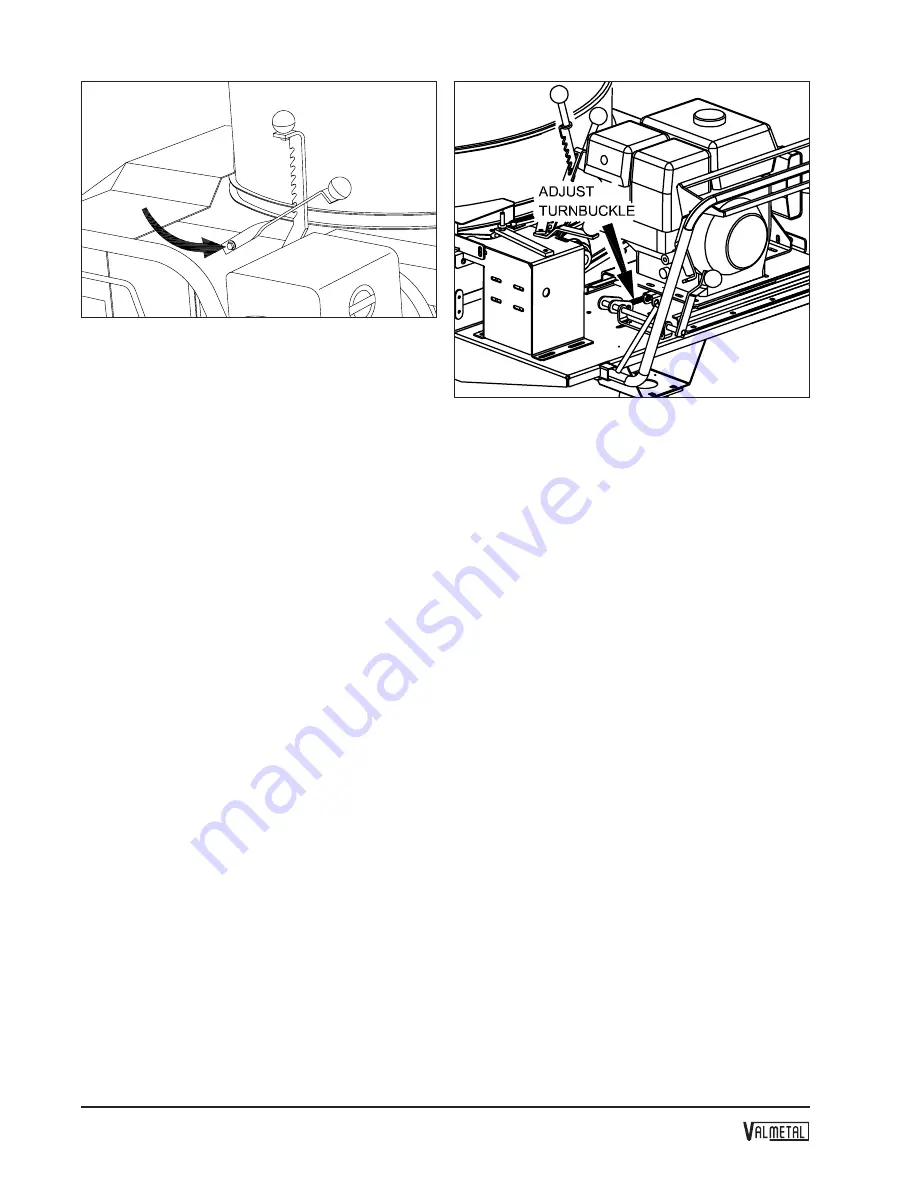

6. Turn the turnbuckle on the control lever to pro-

vide more movement on the idler pulley (fig. 25).

7. Recheck the belts tension. If the turnbuckle

does not provide sufficient adjustment to tighten

the belts, the belts will have to be replaced.

5.2.4.2 BELTS REPLACEMENT

To replace the belts, follow this procedure

1. Clear the area of bystanders, especially small

children.

2. Stop engine, shut off fuel supply lever, remove

ignition key (electric start models), disengage all

drives and wait for all moving parts to stop.

3. Move the turnbuckle until the idler pulley is in its

highest position.

4. Loosen speed reducer mount holding bolts and

remove all rotor V-belts.

5. Install the new belts and reinstall the reducer v-

belt

6. Tension and tighten reducer mount bolts.

7. Adjust the turnbuckles to give the required belt

tension.

8. After 10 hours of running, check the belts ten-

sion. Adjust as required.

24

Fig. 25

Rotor drive turnbuckle

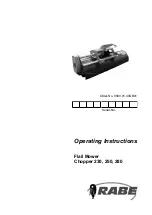

Fig. 24

Grate control lever