8000015884_00 Installation and maintenance instructions

79

B

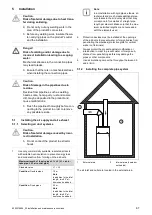

Annual inspection and maintenance work

–

Overview

No.

Work

1

Check that the safety devices are functioning properly.

2

Check the refrigerant circuit for leak-tightness.

3

Check the hydraulic circuit for leak-tightness.

4

Check that the safety assembly is working properly.

5

Check whether the components of the refrigerant circuit show any signs of rust or traces of oil.

6

Check the unit's components for wear.

7

Check whether the unit's components are defective.

8

Check that the cables are securely seated on the connection terminals.

9

Check the electrical installation in accordance with the applicable standards and regulations.

10

Check the product's earthing.

11

Check the evaporator for ice formation.

12

Remove the dust from power supply connections.

13

Clean the evaporator carefully to avoid damaging the fins. Ensure that air circulation through the entire circuit, including

the air intake, is not impeded.

14

Check that the fan runs freely and is clean.

15

Check whether the condensate drains off without any problems.

16

Check the scale deposition on the immersion heater. If the layer of limescale is thicker than 5 mm, you must replace the

immersion heater.

17

Record the inspection/maintenance work carried out.

C

Fault messages

–

Overview

Fault code

Description

Possible cause

Solution

Temporary operation

buS

–

PCB defective

–

Bus connection to the

display is faulty

–

Display defective

–

Overvoltage in the

power grid

–

Cabling fault in the

power supply connec-

tion (low-tariff contact

or external fan control

system)

–

Damage during trans-

port

–

Replacing the PCB

–

Replacing the display

PCB

–

Replacing the display

connection cable

Product decommissioned.

T_AI R

Air temperature sensor

defective (extracted air)

–

Sensor defective

–

Sensor not connected

to the PCB

–

Sensor cable damaged

Replace the sensor

Heat pump decommis-

sioned.

The selected back-up

heater keeps the water

temperature at 38 °C.

T_DE FROST

Evaporator temperature

sensor defective

(Defrosting temperature)

–

Sensor defective

–

Sensor not connected

to the PCB

–

Sensor cable damaged

Replace the sensor

Heat pump decommis-

sioned.

The selected back-up

heater keeps the water

temperature at 38 °C.

T_WA TER

Water temperature sensor

defective

–

Sensor defective

–

Sensor not connected

to the PCB

–

Sensor cable damaged

Replace the sensor

Heat pump decommis-

sioned.

CLOC K

Time

–

Overvoltage in the

power grid

–

Damage during trans-

port

–

Replacing the display

PCB

–

Replacing the display

connection cable

Operating times are no

longer considered:

Target temperature for do-

mestic hot water is per-

manently maintained (no

signal on connection plug

numbers 1 and 2).

Содержание aroSTOR VWL B 270/5

Страница 239: ......