5.1 Visual inspection and preparation

Before putting the valve and the equipment into operation, per-

form a visual inspection of all functional parts. Check whether

all bolted connections have been properly fastened.

5.2 Function check and pressure test

Warning!! The pressure exerted on the closed valve must not

exceed its nominal pressure (see technical data sheet KAT

1543-A). When a pressure test is performed on the pipeline

during which the test pressure exceeds the permissible rated

pressure in the closing direction of the non-return valve, pres-

sure compensation must be ensured via a bypass.

Prior to any tests, newly installed pipeline systems should be

carefully purged to remove all foreign particles. If residues or

dirt particles are left in the pipeline, they may clog the installa-

tions during the purging procedure. This may impair the

function of the valve or even obstruct it completely.

When using detergents / disinfectants, make sure they do

not attack any of the valve materials.

5. Set-up and operation of the valve

6.1 General safety instructions

Prior to the performance of inspection and maintenance work

on the valve or its assemblies, shut-off the pressurised pipeline,

depressurise it and secure it against inadvertent activation.

Depending on the kind and dangerousness of the fluid convey-

ed, comply with all required safety regulations!

After completing the maintenance works and before resuming

operation, check all connections for proper fastening and

tightness. Perform the steps described for initial set-up as

described under Section 5 "Set-up and operation".

Statutory and local provisions as well as the safety and accident

prevention regulations must be observed and complied with at

all times.

Couplings and connections must never be disassembled when

they are under pressure.

Servicing, maintenance and inspection work as well as the

replacement of spare parts must only be done qualified staff.

The plant operator is responsible for determining the suitability

of the staff or for ensuring the relevant qualifications. In case the

operator's employees do not have the qualifications required,

they need to attend a training course. This training course can

e.g. be held by VAG Service employees.

In addition to this, the plant operator needs to ensure that all

employees have understood these Operation and Maintenance

Instructions as well as all further instructions referred to in them.

Protective equipment such as safety boots, safety helmets,

goggles, protective gloves etc. must be worn during all work

6. Maintenance and repair

requiring such protective equipment or for which such protec-

tive equipment is prescribed.

Improper or wrong use of the valve should be avoided. Prior to

the performance of any work on the valve and equipment it

must be ensured that the relevant pipeline section has been

depressurised and/or de-energised.

6.2 Inspection and operation intervals

The condition and function of the diaphragm should be

checked at least once per year (DVGW Instruction Sheet W

392).

In case of extreme operating conditions inspection should be

performed more frequently.

6.3 Maintenance work and replacement of

parts

For information about the spare parts and wearing parts nee-

ded, please refer to the spare parts list in Section "6.3.1

Design".

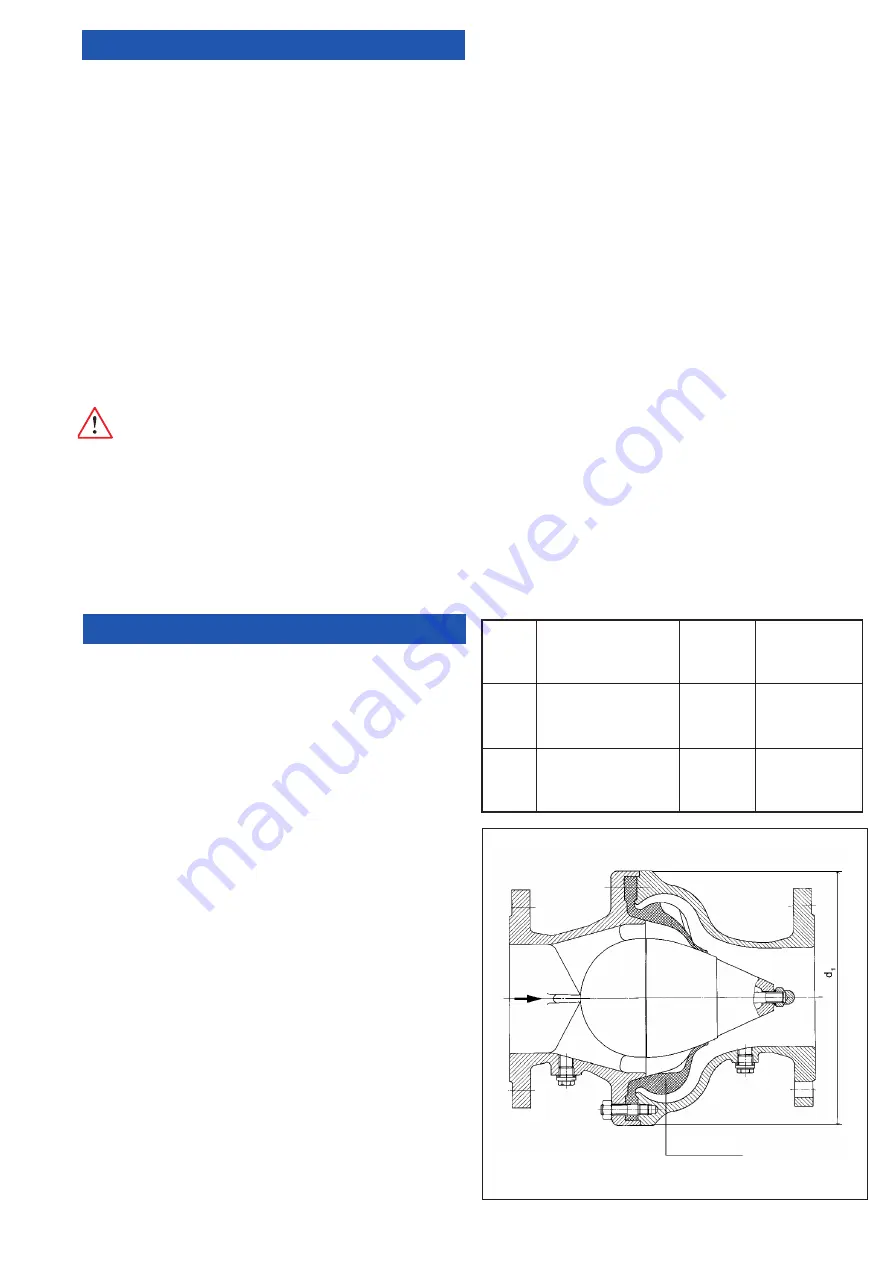

6.3.1 Design

Item

Designation

Material

d1 dimensions

in mm

1

Circular diaphragm

NBR

150, 175, 220,

292, 374, 446,

550,645, 720

1

Circular diaphragm

EPDM

150, 175, 220,

292, 374, 446,

550,645, 720

1