OPERATOR MANUAL

PREVENTATIVE MAINTENANCE

WARNNING: Before performing any maintenance on the machine, be sure that

the power is turned off, or the batteries are disconnected!

WARNNING: Repairs are to be completed by authorized service centers only.

Any repairs completed by unauthorized persons will avoid the warranty.

DAILY MAINTENANCE

1) Remove pad driver / brush and clean with approved cleaner.

2) Drain recovery and solution tanks completely and rinse out with clean water. Visually check

the recovery tank for debris and clean out as necessary.

3) Raise squeegee assembly off floor and wipe it down with a damp towel. Be sure to store the

squeegee in the up position.

4) Remove the float shut-off assembly and rinse it out with clean water.

5) Clean machine with an approved cleaner and a damp towel. Don’t spray water to clean the

outside of machine to avoid damage to motor and wiring.

6) Unplug vacuum motor from power source and hose cuff & remove the drain hose from the

holder prior to removing the recovery tank when performing maintenance.

7) Check the condition of the squeegee blade wiping edge, rotate blade or replace it if worn.

UN18C

10

MOTOR MAINTENANCE

1) Contact your local UnoClean Distributor for any motor maintenance.

2) Check the motor brushes every 250 hours, Replace the brushes when they are worn to a

length of 10mm or less.

MONTHLY MAINTENANCE

1) Inspect and clean the recovery tank cover seal. Replace it if damaged.

2) Lubricate all grease points and pivot points with silicon spay and approved grease.

3) Check the machine for loose nuts and bolts.

4) Check the machine for leaks.

MACHINE STORAGE

1) Always store the machine indoors and in its upright position.

2) Always store the machine in a dry area.

3) Always take off the pad driver / brush before storage.

4) Always store the machine with the squeegee assembly raised off the floor.

5) If storing in an area which may reach freezing temperatures, be sure to drain all fluids from the

machine prior to storage(include the filter). Any damage caused by freezing temperatures will not

be covered by the warranty.

6) Drain the recovery tank and keep the cover tank open so that it can "breathe" during storage.

7) Drain the solution tank of all fluid.

Содержание UN18C

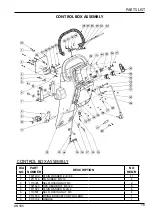

Страница 13: ...PARTS LIST UN18C 13 RECOVERY TANK ASSEMBLY ...

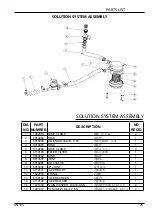

Страница 16: ...PARTS LIST UN18C 16 SOLUTION TANK ASSEMBLY ...

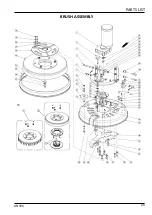

Страница 20: ...PARTS LIST UN18C 20 BRUSH ASSEMBLY 23 ...

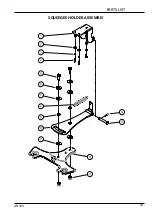

Страница 23: ...PARTS LIST UN18C 23 SQUEEGEE HOLDER ASSEMBLY ...

Страница 26: ...UN18C 26 SQUEEGEE ASSEMBLY PARTS LIST ...

Страница 29: ...OPERATOR MANUAL UN18C 29 WIRING DIAGRAM ...