10. Close (A) Low Side and (B) High Side manifold valves.

11. Disconnect (C) Blue EZ Turn Hose from refrigerant cylinder.

12. Disconnect (E) Red EZ Turn Hose from (C) Blue Hose EZ Access “T” fitting.

13. The hoses have now been purged of non-condensable gases with the

refrigerant needed for service.

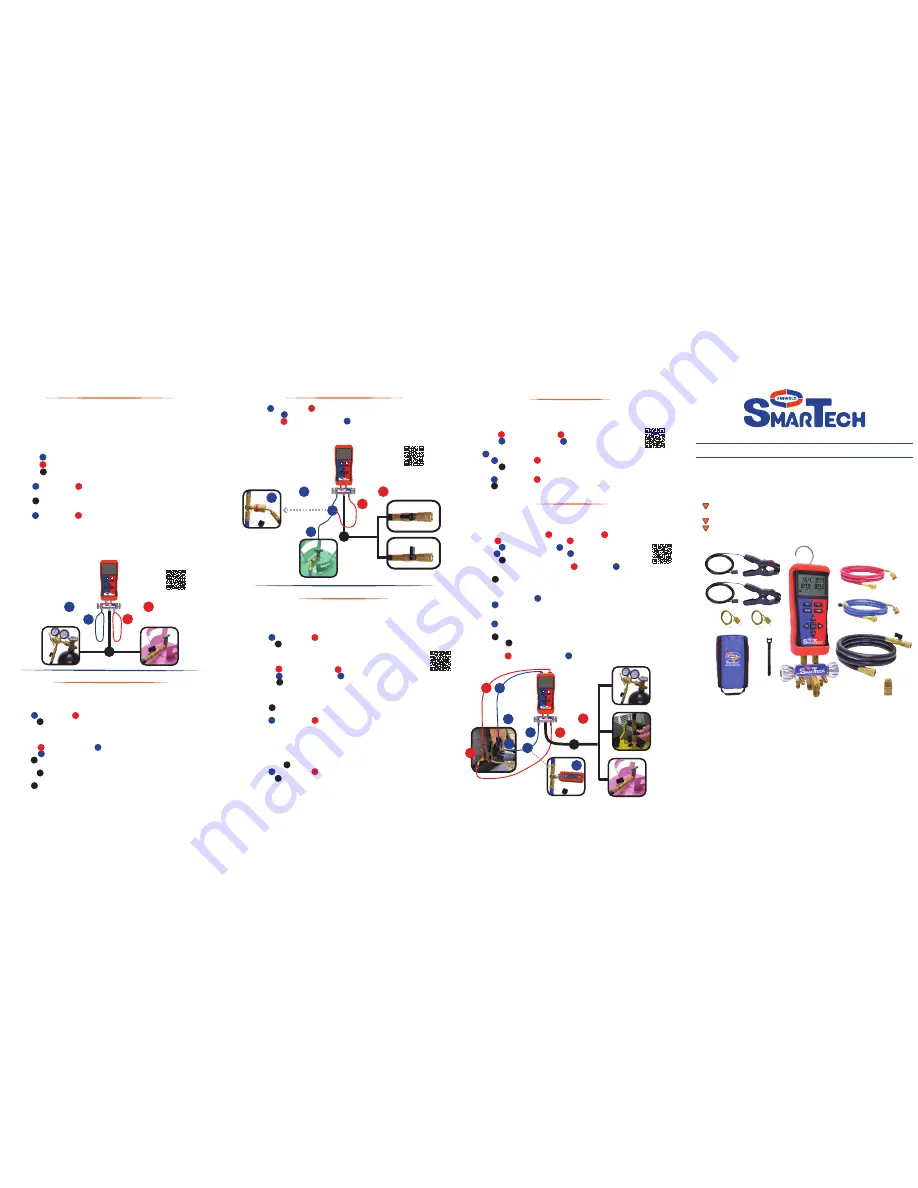

USER MANUAL - PART# USMAN5

Uniweld SmarTech Wireless Digital Manifold

FOR USE BY PROFESSIONALS. This manifold is designed for use by technically

trained refrigeration and air conditioning service technicians, due to the

unusually HIGH PRESSURE AND HAZARDOUS GASES IN ALL SYSTEMS,

misapplication could result in injury or death. The manufacturer warns

against the sale of this product to, or its use by, other than professional

trained personnel.

WARNING: Read carefully and completely before using equipment.

Keep for reference and store in back of protective case.

WARNING: Always wear safety goggles when working with refrigerants.

WARNING: CALIFORNIA PROPOSITION 65: This product contains chemicals

known to the State of California to cause cancer and birth defects or other

reproductive harm

Package Contents

1. SmarTech Wireless Digital Manifold w/ Rubber Boot

2. (1) Blue and (1) Red Temperature Clamp K-Type with 6 Ft. lead

3. (2) Thermocouple Bead Probes K-Type

4. (1) Red 5 Ft. EZ Turn® Anti-Blowback Hose

5. (1) Blue 5 Ft. EZ Turn® Anti-Blowback Hose with 1/4” EZ Access “T” Fitting™

6. (1) Black 5 Ft. Fast-Flo 3/8” Vacuum & Charging Hose with Ball Valve

7. (1) Adaptor 3/8” MF x 1/4” FF

8. SmarTech Protective Padded Case

9. (6) AA Batteries (not shown)

10. (10) Velcro Cable Tie Straps

OI0047

!

!

!

The SmarTech Digital Manifold is extremely accurate and can be used to pressure

test the hoses and manifold valves for leaks. Note: The POE oil used in R410A is very

aggressive and causes the rubber seals in the hoses and manifold valve stems to

wear rapidly; they may need replacing every couple of months depending on usage.

It is recommended to check your manifold and hoses regularly for leaks due to

normal wear on rubber gaskets and seats.

1. Connect (C) Blue EZ Turn Hose to manifold 45º hose holder fitting.

2. Connect (E) Red EZ Turn Hose to manifold 45º hose holder fitting.

3. Connect (D) Black 3/8” Hose with Ball Valve open to nitrogen regulator

using the 3/8”x1/4” adaptor.

4. Open (A) Low Side and (B) High Side manifold valves.

5. Open nitrogen tank valve and set delivery pressure between 400 to 500 psi.

6. Close (D) Black 3/8” Hose Ball Valve. A slight pressure drop is normal as the hoses

stretch under pressure but will stabilize after a couple of minutes.

7. Close (A) Low Side and (B) High Side manifold valves.

8. If digital pressure readings are stable the hoses and manifold are

functioning properly.

9. If the pressure reading continues to decrease there is a leak in the hoses or

manifold that must be repaired. Determine origin of the leak and replace

the gaskets and O-rings as needed. Repeat pressure test.

Manifold and Hoses Leak Test

Prior to purging the hoses with the refrigerant needed for service it may be

necessary to discharge unwanted refrigerant or nitrogen from the hoses.

1. Open (A) Low Side and (B) High Side manifold valves.

2. Aim the (D) Black 3/8” Hose Ball Valve in a safe direction and open

the ball valve to discharge the unwanted refrigerant or nitrogen from the hoses.

3. The digital pressure readings for both Hi and Lo should read zero before

continuing to the next step of purging the hoses with refrigerant.

4. Connect (E) Red EZ Turn Hose to (T) Blue Hose EZ Access “T” fitting.

5. Connect (C) Blue EZ Turn Hose to refrigerant cylinder.

6. Close (D) Black 3/8” Hose Ball Valve.

7. Open refrigerant cylinder valve.

8. Aim the (D) Black 3/8” Hose Ball Valve in a safe direction, open ball valve

and begin purging non-condensable gases.

9. Close (D) Black 3/8” Hose Ball Valve when all non-condensable gases have

been purged.

The SmarTech Digital Manifold is extremely accurate and can be used to

pressure test the system for leaks. Prior to pressure testing with nitrogen it

may be necessary to discharge unwanted refrigerant from the hoses.

1. Open (A) Low Side and (B) High Side manifold valves.

2. Aim the (D) Black 3/8” Hose Ball Valve in a safe direction and open

the ball valve to discharge the unwanted refrigerant from the hoses.

3. The digital pressure readings for both Hi and Lo should read

zero before continuing to the next step.

4. Connect (E) Red EZ Turn Hose to (F) High Side service fitting.

5. Connect (C) Blue EZ Turn Hose to (G) Low Side service fitting.

6. Connect (D) Black 3/8” Hose with Ball Valve open to nitrogen regulator

using the 3/8”x1/4” adaptor.

7. Open nitrogen tank valve and set delivery pressure to system manufacturer’s

recommended test pressure.

8. Close (D) Black 3/8” Hose Ball Valve. A slight pressure drop is normal as the

hoses stretch under pressure but will stabilize after a couple of minutes.

9. Close (A) Low Side and (B) High Side manifold valves.

10. If after a few minutes the pressure reading continues to decrease there

is a system leak. The leak must be repaired then repeat the system

pressure test.

11. If after a few minutes the digital pressure readings are stable the system is

leak-free.

12. Close the nitrogen cylinder valve.

13. Disconnect (D) Black 3/8” Hose from the nitrogen regulator.

14. Open (A) Low Side and (B) High Side manifold valves.

15. Aim the (D) Black 3/8” Hose Ball Valve in a safe direction and open

the ball valve to discharge the nitrogen from the system and hoses.

16. Proceed with evacuating the system.

Prior to charging a system with refrigerant the hoses must be evacuated or purged with

the refrigerant needed for service, see Discharge and Purge Hoses before proceeding.

1.

Turn system off and connect (E) Red EZ Turn Hose to (F) High Side service fitting.

2.

Attach (H) Red Temperature Clamp to (F) High Side copper tubing.

3.

Connect (C) Blue EZ Turn Hose to (G) Low Side service fitting.

4. Attach (J) Blue Temperature Clamp to (G) Low Side copper tubing.

5. Connect (D) Black 3/8” Hose with Ball Valve closed to refrigerant cylinder.

6.

If this is a new system installation, open (F) High Side and (G) Low Side

condenser service valves.

7.

Open (D) Black 3/8” Hose with Ball Valve and refrigerant cylinder valve.

8.

Turn system on; SmarTech Superheat and Subcooling features can be used at this time

to properly charge the system for maximum efficiency and optimal performance.

9.

To add refrigerant open (A) Low Side manifold valve.

10. Close (A) Low Side manifold valve and let the system temperatures and pressures

stabilize. Check Superheat and Subcooling “Smart Charge Zone”, if additional

refrigerant is needed repeat steps 9 and 10 until the “Smart Charge Zone” is “Green” .

11. Close (A) Low Side manifold valve when desired amount of refrigerant has

been added.

12.

Close (D) Black 3/8” Hose Ball Valve and refrigerant cylinder valve.

13. Disconnect (D) Black 3/8” Hose with Ball Valve from refrigerant cylinder and

connect to manifold hose holder fitting.

14. Disconnect (E) Red EZ Turn Hose and (C) Blue EZ Turn Hose from system and

connect to manifold hose holder fittings.

Prior to evacuating the system it may be necessary to discharge unwanted

nitrogen or refrigerant from the hoses, see Discharge & Purge Hoses steps 1-2

before proceeding.

1. Connect (E) Red EZ Turn Hose to (F) High Side service fitting.

2. Connect (C) Blue EZ Turn Hose to (G) Low Side service fitting.

3. Optional: Connect (Uniweld Part# UVG) Digital Vacuum Gauge

to (T) Blue Hose EZ Access “T” fitting.

4. Open (A) Low Side and (B) High Side manifold valves.

5. Connect (D) Black 3/8” Hose with Ball Valve open to vacuum pump.

6. Evacuate system according to manufacturer’s specification.

7. Close (A) Low Side and (B) High Side manifold valves.

8. Close (D) Black 3/8” Hose Ball Valve and disconnect from the vacuum pump.

9. Turn vacuum pump off and proceed with charging system with refrigerant.

A

A

C

T

C

E

E

A

B

B

B

D

D

MENU

PAIR

O

Enter

Right

––––

Hold

Left

––––

Max Min

Down

––––

–

Up

––––

+

D i g i t a l M a n i f o l d

A

C

E

D

B

LOW

HIGH

MENU

PAIR

O

Enter

Right

––––

Hold

Left

––––

Max Min

Down

––––

–

Up

––––

+

D i g i t a l M a n i f o l d

A

J

H

C

G

E

D

B

F

LOW

HIGH

NITROGEN

NITROGEN

REFRIGERANT

REFRIGERANT

VACUUM

Figure 2

Figure 3

Figure 1

MENU

PAIR

O

Enter

Right

––––

Hold

Left

––––

Max Min

Down

––––

–

Up

––––

+

D i g i t a l M a n i f o l d

A

C

T

E

D

B

LOW

HIGH

CLOSED

T

T

T

Multi-function ¼”

Male Flare “T” Fitting

built into the blue hose

for Simplified

Purging and Charging

Refrigerant.

EZ Access “T” Fitting™

OPEN

Discharge and Purge Hoses

Discharge and Purge Hoses

Pressure Test System

Evacuating System

Charging System

See Figure 1

See Figure 2

See Figure 3

See Figure 3

See Figure 3

A

A

C

E

B

B

D

D

D

A

B

D

D

A

A

A

A

A

C

J

T

C

C

G

G

G

G

E

H

E

E

F

F

F

F

G

F

B

B

D

D

D

D

D

D

A

C

T

E

B

D

D

D

D