Page 42 of 44

Page 43 of 44

MAN.500.REVD.06302015

Limited Warranty

I. Limited Warranty

1. Limited Warranty. Universal Analyzers, Inc (UAI) offers a limited warranty on each of its products against failure due to

defects in material and workmanship for a period ending the earlier of (i) fifteen (15) months from the date of the invoice

relating to the sale of the product and (ii) twelve (12) months from the date of installation of the product (collectively,

the “Initial Warranty”). During the Initial Warranty, UAI offers a limited warranty against failure due to defects in material

and workmanship on each part of a product repaired or replaced by an authorized service person for a period ending

the later of (a) the remaining term of the Initial Warranty of the product and (b) ninety (90) days from the date of such

repair or replacement. After expiration of the Initial Warranty, UAI offers a limited warranty against failure due to defects

in material and workmanship on each part of a product repaired or replaced by an authorized service person for a period

ending ninety (90) days from the date of such repair or replacement. UAI further offers a limited warranty that the products

and parts it sells will conform to UAI’s written specifications therefor. The foregoing limited warranties cover parts and

labor only and UAI does not warrant and will not reimburse the buyer of its products (“Buyer”) for any costs relating to

the access by service persons of UAI to the product at issue. The foregoing limited warranties cover only the repair or

replacement of defective parts and such determination will be in the sole discretion of UAI. In its sole discretion, UAI may

make repairs or replacements under these limited warranties with either new or refurbished parts. To the extent Buyer’s

product cannot be remedied under these limited warranties through repair or replacement of parts, Buyer may return the

product for a refund of the purchase price, less a reasonable reduction in such purchase price equal to the depreciation

expense incurred by Buyer relating to such product. The limited warranties of this Section I.1. are further subject to those

warranty exclusions set forth below in Section I.2.

2. Limited Warranty Exclusions. Excluding the warranties provided for in Section I.1., UAI provides all products to Buyer

“as-is,” without any other warranty of any kind. UAI disclaims any and all express or implied warranties of merchantability,

fitness for a particular purpose and non-infringement of the intellectual property of others. UAI makes no warranty, express

or implied, as to the design, sale, installation or use of its products. UAI’s warranties will not be enlarged by, nor will any

obligation or liability of UAI arise due to UAI providing technical advice, facilities or service in connection with any product.

There is no warranty by UAI with respect to any product’s: (i) uninterrupted or error-free operation; (ii) actual performance,

other than the product’s capability to meet UAI’s specifications therefor; (iii) removal or installation from a worksite or

process; (iv) electronic components or associated accessories (including without limitation circuit boards and integrated

circuits); (v) maintenance (including without limitation gasket and seal replacements, adjustments, minor repairs and

other inspection requirements, preventative or otherwise); (vi) use under inappropriate conditions or not in accordance

with operating instructions; or (vii) use in connection with the operation of a nuclear facility. There is no warranty for

labor expenses associated with field repairs or the repair or replacement of defective parts in the engine or power unit

of any product if such product has been in the possession of the owner or operator for greater than twelve (12) months.

There is no warranty for products determined to be, in UAI’s sole discretion, damaged as a result of (a) misuse, neglect

or accident; (b) improper application, installation, storage or use; (c) improper or inadequate maintenance or calibration;

(d) operation outside of the published environmental specification; (e) improper site preparation or maintenance; (f)

unauthorized repairs or replacements; (g) modifications negligently or otherwise improperly made or performed by

persons other than UAI; (h) Buyer-supplied software or supplies; (i) use in conjunction with or interfacing with unapproved

accessory equipment; (j) use of ABC-style or dry powder fire suppression agents; or (k) leaked sample materials. To the

extent a UAI product is used in connection with the operation of a nuclear power facility, Buyer agrees to indemnify and

hold UAI harmless from any and all actions, claims, suits, damages and expenses arising from such use. UAI provides no

warranty on the oral representations made by its personnel while they are attempting to assist Buyer in the operation of

a product. This Standard Limited Warranty does not apply to items consumed by the products during their ordinary use,

including but not limited to fuses, batteries, paper, septa, fittings, screws, fuses, pyrolysis, dryer or scrubber tubes, sample

boats, furnaces or UV lamps.

3. Non-UAI Products. UAI does not in any way warrant products it does not manufacture except to the extent the warranty

of the manufacturer of the product at issue passes through or is otherwise assigned to UAI. If a manufacturer warranty

is so assigned to UAI, UAI will only be bound to comply with the length of time associated with such warranty. All other

terms of such warranty will be governed by this Standard Limited Warranty and UAI’s General Terms and Conditions

incorporated herein by reference.

Содержание 500 series

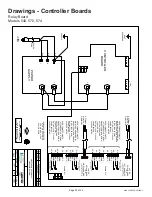

Страница 12: ...Page 12 of 44 MAN 500 REVD 06302015 Electrical Connections Model 520 ...

Страница 13: ...Page 13 of 44 MAN 500 REVD 06302015 Electrical Connections Model 530 ...

Страница 14: ...Page 14 of 44 MAN 500 REVD 06302015 Electrical Connections Model 540 ...

Страница 15: ...Page 15 of 44 MAN 500 REVD 06302015 Electrical Connections Model 560 ...

Страница 16: ...Page 16 of 44 MAN 500 REVD 06302015 Electrical Connections Model 570 ...

Страница 17: ...Page 17 of 44 MAN 500 REVD 06302015 Electrical Connections Model 574 ...

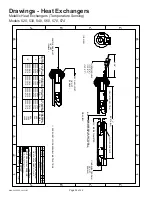

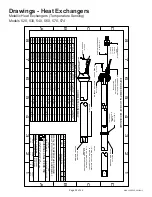

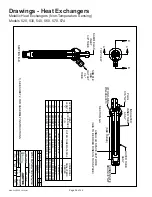

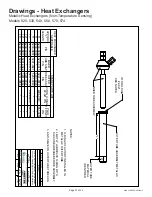

Страница 23: ...Page 23 of 44 MAN 500 REVD 06302015 Drawings Model 520 ...

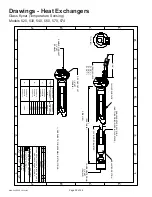

Страница 24: ...Page 24 of 44 MAN 500 REVD 06302015 Drawings Model 530 ...

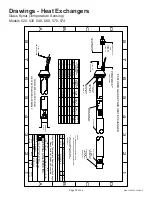

Страница 25: ...Page 25 of 44 MAN 500 REVD 06302015 Drawings Model 540 ...

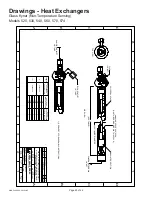

Страница 26: ...Page 26 of 44 MAN 500 REVD 06302015 Drawings Model 560 ...

Страница 28: ...Page 28 of 44 MAN 500 REVD 06302015 Drawings Model 570 ...