Vision™ OPLC™

Unitronics

3

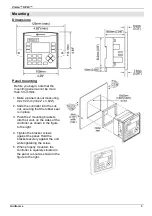

Mounting

Dimensions

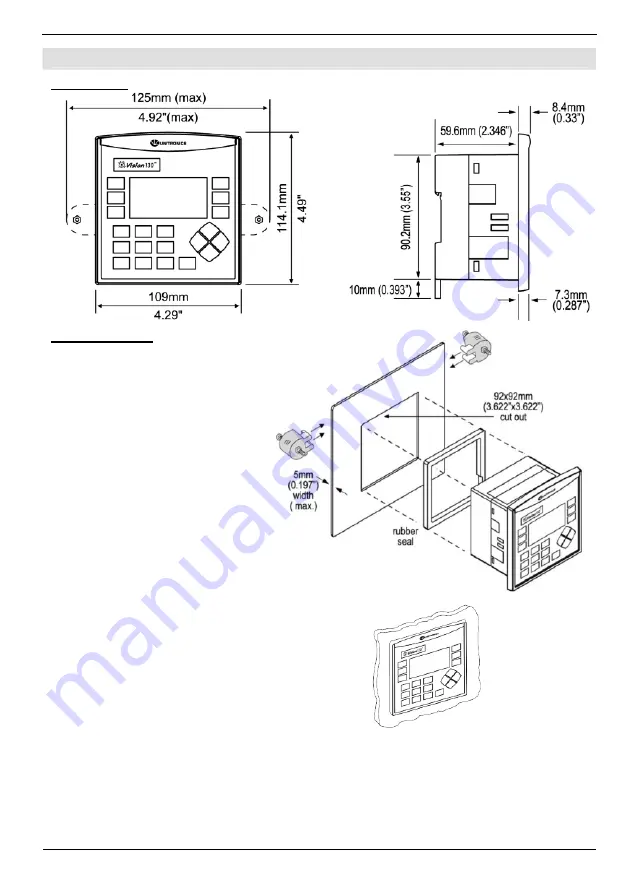

Panel mounting

Before you begin, note that the

mounting panel cannot be more

than 5 mm thick.

1. Make a panel cut-out measuring

92 x 92 mm (3.622” x 3.622”).

2. Slide the controller into the cut-

out, ensuring that the rubber seal

is in place.

3. Push the 2 mounting brackets

into their slots on the sides of the

controller as shown in the figure

to the right.

4. Tighten the bracket screws

against the panel. Hold the

bracket securely against the unit

while tightening the screw.

5. When properly mounted, the

controller is squarely situated in

the panel cut-out as shown in the

figure to the right.