6

systems of high cycles should be inspected frequently. At a minimum, semi-

annual inspections are recommended. Points of inspection should be at a

minimum:

1. All end joints, cover joints and packing boxes should be inspected for leakage.

2. Bolts should be checked for tightness, a torque of 90 foot pounds is

recommended for gasketed joints.

3. Inspection of the valve during operations is recommended so that the outside

linkages can be inspected for proper operation.

4. Inspection of the packing box is required to assure no leakage is evident. If

leakage exists replace o-rings. Do not tighten Packing Nut (#22) to stop the leak.

Caution: O-rings should not be changed or added in an active valve. Valve

should be isolated to prevent injury or damage to valve and operator.

5. Inspection of interior of valve is not necessary unless improper operation is

witnessed or leakage beyond the allowable rate is experienced. The interior of

the valve and the internal components can be inspected by removing the valve

cover. Cover gasket should be replaced any time this joint is broken. Never re-

install a used cover gasket.

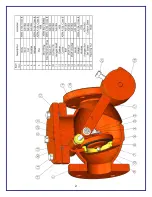

RECOMMENDED SPARE PARTS QTY PER VALVE

Disc seat ring, Buna-N (NBR), 1

Cover gasket, Buna-N, 1

O-rings, Buna-N, 2

O-rings, Buna-N, 1

LUBRICATION

Under normal operation, lubrication is not required to maintain proper operation

of components or assembled units. User should review Typical Maintenance

Summary Form (below) for additional information and instructions.

TROUBLESHOOTING

Possible symptoms/ Cause/ Corrective action

End joint leakage: Tension on flange bolts is relaxed. Tighten flange bolts/nuts in

a crisscrossed pattern.

Cover gasket leakage: Tension on cover bolts is relaxed. Tighten cover bolts in

a crisscrossed pattern. Should leakage continue, replace cover gasket.

Содержание 7700 Series

Страница 2: ...2...