5

a. Existing fuel-fired equipment shows evidence of

back puffing, smoke roll-out, inefficient operation,

or excessive smell in the living area.

b. Opening a window or door alleviates any of the

above problems or symptoms.

c. The building is constructed with a well-sealed va-

por barrier, tight fitting windows, or has powered

exhaust fans.

d. Excessive condensation on windows in the winter.

e. The building has a ventilation system installed.

f. If, once installed, the solid-fuel appliance does not

draw steadily, burns poorly or inefficiently, back-

drafts or experiences back-puffing when adding

fuel.

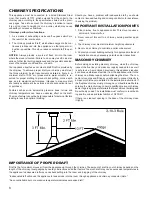

VENTING (DRAFT) REQUIREMENTS

The chimney flue is a critical component to the proper and

efficient operation of any heating appliance. Heating appli

-

ances do not create draft, draft is provided by the chimney.

This appliance requires a draft of 0.05 in. water column

(0.1 Pa) at the flue collar.

WARNING: RISK OF FIRE - EXCESSIVE DRAFT CAN

CAUSE OVERFIRING AND A POSSIBLE STRUCTURE

FIRE. DO NOT OPERATE THIS APPLIANCE WITH

THE FLUE DRAFT EXCEEDING 0.06 in. w.c. (0.1 Pa).

To achieve proper draft, your chimney must meet three

minimum height requirements; minimum height from top of

appliance (15 ft. total height from top of appliance), minimum

height above roof penetration (3 ft.), and minimum height

(2 ft.) above highest point of roof within a 10 ft. diameter

from the chimney.

The chimney must also meet minimum and maximum

cross sectional requirements. For that reason a continu

-

ous 6˝ stainless steel liner from the flue collar to the top

of the chimney is required. A stainless steel adapter is

recommended for fastening the stainless steel liner to the

flue collar. The male (or crimped) end of the adapter must

be installed inside the flue collar to allow condensation or

creosote in the liner to drain back into the firebox. Chimney

liners and/or adapters must be permanently fastened using

a minimum of three (3) screws at each connection.

Chimneys outside of the home or on an exterior wall are

difficult to keep at operating temperatures and may result

in increased creosote buildup, less draft, back drafting

problems and poor appliance performance and should be

avoided.

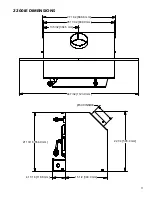

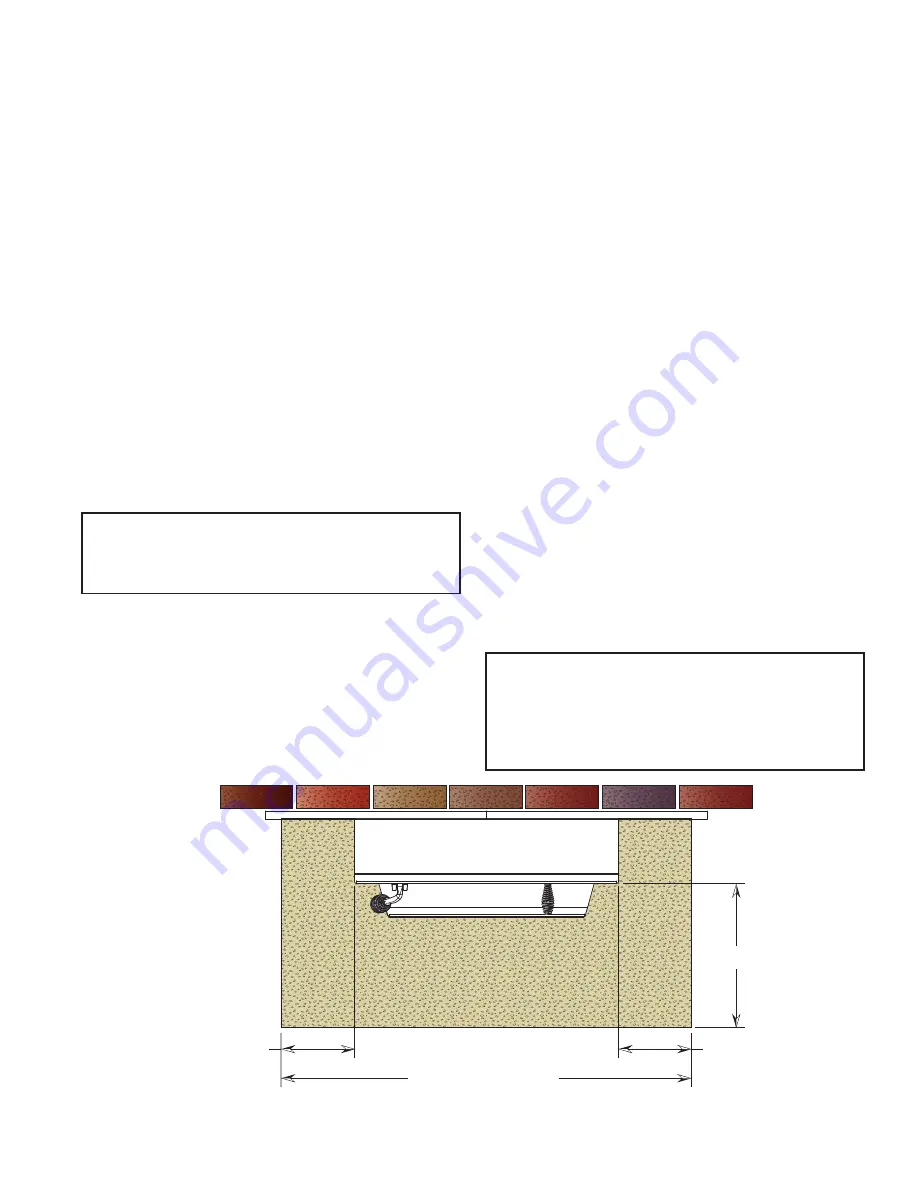

FLOOR PROTECTOR

A solid non-combustible floor, concrete or solid masonry,

must extend 6˝ to either side of the body of the appliance

and 12˝ in front of the face of the appliance.

When combustible flooring falls within these minimum

dimensions, it must be covered with a listed floor protec

-

tor meeting the requirements of UL 1618, such as Hy-C

or Imperial Model UL 2840BK or equivalent with 0.84 R-

factor, 1” thick. (Note: to calculate R-value of alternative

materials see

Floor Protector Material Calculations

at

the back of this manual.) A grouted ceramic floor tile that

meets local building codes and the minimum 0.84 R-factor

requirements is considered a durable equivalent.

PRE-INSTALLATION REQUIREMENTS

WARNING: RISK OF FIRE - DO NOT ALLOW COM-

BUSTIBLE MATERIALS (CARPET, FURNITURE,

FUELS) TO BE PLACED ON OR COVER THE FLOOR

PROTECTOR. ALL COMBUSTIBLE MATERIALS MUST

REMAIN OUTSIDE OF THE MINIMUM CLEARANCE

DIMENSIONS.

US - 38 inches [965mm]

CAN - 42 inches [1.06M]

US - 6 in. [152mm]

CAN - 8 in. [203mm]

US - 6 in. [152mm]

CAN - 8 in. [203mm]

12 inches [305mm]

FLOOR PROTECTOR

Minimum Floor Protector Specifications

Содержание Country Hearth 2200IE

Страница 17: ...17 NOTES...