650.67-N2V

035-15881-402 REV. A (1199)

6

Unitary Products Group

It is recommended that the supply air duct attached to the fur-

nace be provided with a removable access panel. The open-

ing should be accessible when the furnace is installed in

service and should be large enough that smoke or reflected

light may be observed inside the casing to indicate the pres-

ence of leaks in the heat exchanger. The cover panel for this

opening should be attached in such a manner as to prevent

leaks.

A/C USAGE DUCT SYSTEM

1.

When a single (common) duct system is used one of the

following methods shall be used:

a.

The optional cooling coil designed for slide-in instal-

lation with this furnace,

b.

A self-contained A/C unit must be in parallel with

and isolated from the furnace.

2.

If two duct systems are used as could be the case with a

coil-blower or a self-contained A/C unit, the furnace and

A/C unit should be controlled by a single combination

heating and cooling thermostat which will prevent the fur-

nace and A/C unit from operating simultaneously.

RETURN AIR, FILTERS, AND DUCT

CONNECTIONS

RETURN AIR TEMPERATURE

This furnace is designed to be operated in normal household

temperatures. The continuous return air temperature must

not be below 60 ºF or above 85 ºF.

FILTERS

Air filters of adequate size must be used with the return air

supply to this furnace. Failure to do so will cause dirt to accu-

mulate on the furnace blower motor, blower wheel, heat

exchanger and air conditioner coil, resulting in reduced sys-

tem efficiency, erratic control performance, and possible

equipment damage.

Filters are to be mounted at least one inch upstream from the

return connection to the unit. Locating the filter in a crawl

space, attic, or other inaccessible location will result in filters

not being changed as frequently as recommended.

Size filters according to the requirements in Table 2.

DUCT CONNECTIONS

Although these units have been specifically designed for

quiet, vibration free operation, air ducts can act as sounding

boards and could, if poorly installed, amplify the slightest

vibration to the annoyance level.

Where the unit is located adjacent to the living area, the sys-

tem should be carefully designed with cold air strategically

located to minimize transmission through the return air grille.

Although this year-round air conditioner is designed with a

large blower operating at moderate speed, any blower mov-

ing a high volume of air will produce audible noise which

could be objectionable when the unit is located very close to

a living area. It is often advisable to carry the return air ducts

under the floor or through the attic. Such design permits the

installation of air return remote from the living area (i.e., cen-

tral hall).

When installing duct outdoors where it will be exposed to

weather, care must be taken to completely weatherproof both

ducts and insulation. Take any additional measures, such as

flashings and caulking compound, necessary to provide a

good weather seal.

Dampers must be installed when a coil blower or

self-contained cooling unit is employed to prevent

conditioned cool air from coming in contact with

the heat exchanger to avoid moisture condensa-

tion and oxidation (rust), which could allow prod-

ucts of combustion to be circulated into the living

area by the furnace blower resulting in possible

asphyxiation. If dampers are the manually oper-

ated type, a means must be provided to prevent

either the furnace or the A/C unit from operating

(unless dampers are in full heat or cool position).

If a separate heating and separate cooling thermo-

stat is used, a manually operated electrical inter-

lock switch must be installed to prevent

simultaneous operation of both systems and avoid

a possible hazardous condition due to overheating

of the conditioned space.

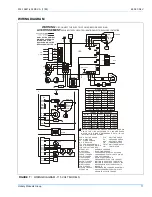

Table 2:

FILTER REQUIREMENTS CHART

H

EAT

I

NPUT

(BTU/HR)

C

OOLING

T

ONS

(N

OMINAL

R

ECOMMENDED

M

IN

.

F

ILTER

A

REA

:

Washable Type

Disposable

Type

50,000-75,000

2.0-2.5

290

480

50,000-100,000

3-3.5

405

675

100,000-

125,000

4

460

765

125,000

5

580

965