035-18547-001-A-0902

4

Unitary Products Group

GENERAL

These heat pump units are designed for outdoor instal-

lation on a roof or at ground level. Every unit is com-

pletely piped and wired at the factory and is shipped

ready for immediate installation. Only the liquid and

vapor lines to the indoor coil, the control wiring and the

main power wiring are required to complete the instal-

lation. Each unit is dehydrated, evacuated, leak tested

and pressure tested at 450 psig before being pressur-

ized with a holding charge of Refrigerant-22 for ship-

ment and/or storage.

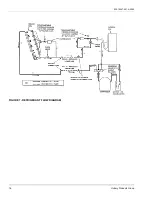

Every unit includes a heavy-duty compressor with line

break overload protection, a suction line accumulator,

a 4-way reversing valve, a filter-drier, an expansion

valve, a distributor, a check valve, and a copper tube/

aluminum fin coil.

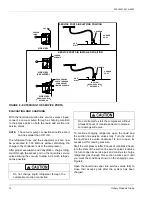

All controls are readily accessible for maintenance,

adjustment and service. All power and control wiring

can be routed through the front of the unit.

SAFETY CONSIDERATIONS

Installer should pay particular attention to the words:

NOTE, CAUTION and WARNING. Notes are intended

to clarify or make the installation easier. Cautions are

given to prevent equipment damage. Warnings are

given to alert the installer that personal injury and/or

equipment damage may result if the installation proce-

dure is not handled properly.

REFERENCE

This instruction covers the installation of the outdoor

unit. For information on the installation of the matching

indoor unit, refer to Part Number 035-18548-001.

All accessories come with a separate installation man-

ual. Refer to Parts Manual for complete listing of

replacement parts on this equipment.

The above form may be ordered from:

Standard Register

2101 W. Tecumseh Rd.

Norman, OK 73069

TOLL FREE Tel.: 877-318-9675

TOLL FREE Fax: 877-379-7920

AGENCY APPROVALS

Design certified by UL as follows:

1.

For use as a cooling/heat pump unit only.

2.

For outdoor installation only.

INSPECTION

As soon as a unit is received, it should be inspected for

possible damage during transit. If damage is evident,

the extent of the damage should be noted on the car-

rier's freight bill. A separate request for inspection by

the carrier's agent should be made in writing. See Form

50.15-NM for more information.

This product must be installed in strict compli-

ance with the enclosed installation instructions

and any applicable local, state, and national

codes including, but not limited to, building,

electrical, and mechanical codes.

Improper installation may create a condition

where the operation of the product could cause

personal injury or property damage.