-

37

-

WS

Series

Advanced air conditioning systems

11. CONTROL PROGRAMS and OPERATION INSTRUCTIONS

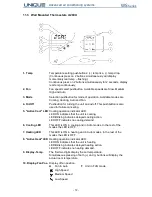

11.1 General

Protection:

The air conditioner is protected by pressure and temperature sensors. The

sensors cut off the unit once extreme and dangerous conditions are detected. The DISPLAY

on the thermostat indicates the failure code as stipulated in the troubleshooting section.

Restart after power failure:

Back-up memory keeps the working data. Once power returns,

the air conditioner will restart and return to its saved data.

The unit can be modified to fail-safe manual restart after power failure (Start-Stop).

Instructions for such modification are available upon request.

Reset and restart after failure:

Once the unit has stopped due to failure, restart is possible

after resetting. Reset the system by pressing ON/OFF button on the room thermostat. Call

the technician for assistance should the failure be repeated.

Restart time delay:

Compressor starting time delay is 1 min. at first start and 3.5 min. before

each restarting. Timer accuracy is ±20 sec.

Evaporator fan control (only for Heat Pump unit):

In cooling mode the fan runs

continuously. In heating mode the fan stops running 15 sec. after compressor stop.

Evaporator fan control (only for units with electrical heating elements):

In cooling mode

the fan runs continuously. In heating mode the fan stops running 40 sec. after the heating

elements are turned off.

Water temperature control (only for Heat Pump unit):

Compressor stops if water

temperature reaches below 4ºC. Compressor restart enabled at water temperature above

10ºC. Failure in water temperature sensor does not stop unit operation. If failure occurs 3

times per hour and/or holds for 1 full hour, signal of failure

ER8

will appear stable and On/Off

press for re-start not allowed. Re-start only by shut-off and switch-on of power supply.

Heating control (only for units with electrical heating elements):

The return air

temperature sensor switches ON the first heating group at room temperature 1ºC lower than

the set temperature. Heating is switched OFF at set point.

Second heating group is switched ON at room temperature 2ºC lower than the set

temperature. Second heating group is switched OFF at 1ºC under set point.

Evaporator coil temperature control:

Compressor stops at coil temperature below 0ºC.

Compressor restart enabled at coil temperature above 8ºC.

Failure in evaporator coil temperature sensor does not stop unit operation.

Return air temperature sensor:

T

hermostats include an incorporated, build-in temperature

sensing element. However, an external sensor (optional) can be added. In such case the

operation of the unit is governed by the selected sensor.

The thermostat temperature setting range is

16ºC

to

30ºC

.

Failure in return air sensor will cause the compressor to run continuously. If unit was set to

"AUTO" operation mode, the compressor will not run.

Air-Flow protection (only for units with electrical heating elements):

To protect the

heating elements from overheating or from operating without flowing air.

A combination of differential pressure flow-switch (for heating elements larger then 12KW)

and temperature sensor immediately cut off the heating elements in case the temperature or

air-flow reaches the pre-set protection values. The fan continues running for additional 15

sec.

Содержание WS Series

Страница 1: ...Service Manual And Advanced air conditioning systems ...

Страница 2: ......

Страница 14: ... 14 WS Series Advanced air conditioning systems 6 1 Refrigeration Cycle Cooling Only ...

Страница 15: ... 15 WS Series Advanced air conditioning systems 6 2 Refrigeration Cycle Heat Pump ...

Страница 40: ... 40 WS Series Advanced air conditioning systems NOTES NOTES NOTES NOTES ...

Страница 41: ......