23

Instruction for the installer

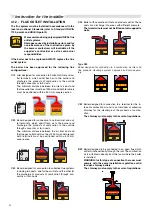

KIT5730C

KIT5820C

KIT5700C

00360357

00361256

00361334

KIT5700C

00361334

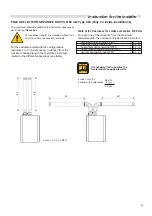

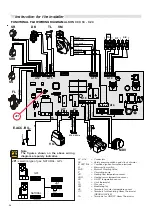

29

5

101,5

237

Fit the rubber spacer, supplied with the

boiler, as shown in the picture.

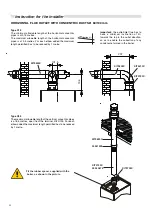

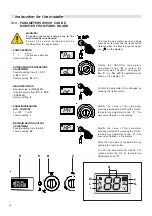

Type C13

The minimum allowable length of the horizontal concentric

pipes is of 0,75 metres.

The maximum allowable length of the horizontal concentric

pipes is of 6 metres. For each elbow added the maximum

length permitted has to be reduced by 1 metre. Moreover, the

flue outlet has to have a minimum inclination of 3% towards

the top in the outlet direction, so as to enable the collection of

any condensate formed in the boiler.

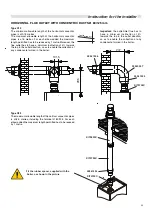

Type C33

The maximum allowable length of the vertical concentric pipes

is of 8,5 metres, including the terminal Ø 80/125. For each

elbow added the maximum length permitted has to be reduced

by 1 metre.

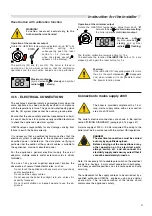

HORIZONTAL FLUE OUTLET WITH CONCENTRIC DUCTS Ø 80/125 mm

Important:

the outlet/inlet flue has to

have a minimum inclination of 3%

towards the top in the outlet direction,

so as to enable the collection of any

condensate formed in the boiler.

inclination 3%

Содержание ALKON R 18

Страница 1: ...ALKON 09 R 18 C 18 R 24 C 24 00333176 2nd edition 10 2011 INSTALLATION AND SERVICING MANUAL...

Страница 46: ......

Страница 47: ......