40

Codes fault

5

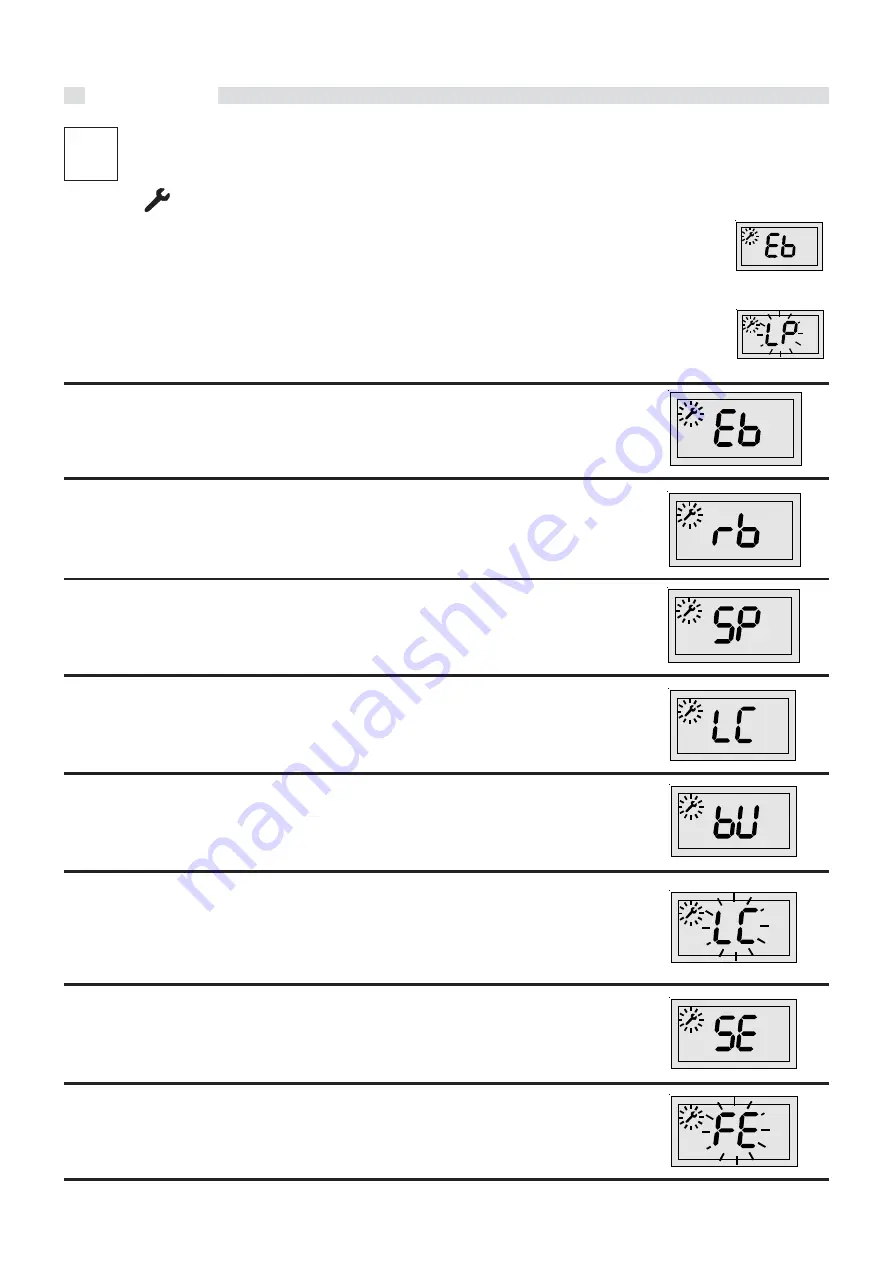

The symbol flashes on the display when the boiler detects a fault.

1) In case of a fault which does not causes the stop of boiler operation, to show the error code it is necessary

to press the reset push button. If the boiler is in stand-by the error code appears in the display also without

pressing the reset push button.

2) In case of an error code which causes the stop of boiler operation, the error code is shown directly on the

display in flashing mode.

Each error is characterized by a priority level: if two errors are detected at the same time, the error code with

higher priority is shown.Here below the list of the known errors.

Outer temperature sensor (priority 0)

Description:

Outer temperaturesensor interrupted

Possible solutions:

Inspect the harness; if necessary replace the outer sensor

.

Heating return temperature sensor (priority 1)

Description:

Return temperature sensor interrupted

Possible solutions:

Inspect the harness; if necessary replace the return temperature sensor

.

Working parameters (priority 2)

Description:

Working parameters corrupted

Possible solutions:

Re-introduce the correct working parameters.

Insufficient circulation (priority 3)

Description:

Insufficient circulation in the primary circuit

Possible solutions:

Inspect the operation of the pump and its speed adjustment

Mistension supply to the burner (priority 4)

Description:

It depends on the electrical supply (Frequency and Voltage out of the standard limits)

Possible solutions:

Wait for the values entering within the limits

Heating flow and return temperature sensors (priority 5)

Description:

Water circulation through primary circuit

very

weak

Possible solutions:

Inspect the operation of the pump and its speed setting; remove possible obstructions of the

C.H. system; clean the possible fouled D.H.W. heat exchanger.

Heating flow and return temperature sensors (priority 6)

Description:

Heating flow and return temperature sensors inverted

Possible solutions:

Inspect the harness

Fan (priority 7)

Description:

Alteration of the fan speed

Possible solutions:

Inspect the operation of the fan and its harness.

°C

°C

°C

°C

°C

°C

°C

°C

°C

°C

FAULT CODES

Содержание ALKON 28 R HE

Страница 1: ...INSTALLATION AND SERVICING MANUAL 00333883 2nd edition 06 2012 ALKON 28 R HE 28 C HE 35 R HE 35 C HE...

Страница 42: ......

Страница 43: ......