29

ENGLISH

Installation Instructions

ATTENTION!

Remove

cap 2,

Insert

the CO2 probe

in hole.

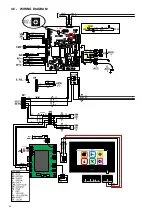

3.11.2 - POSITIONING THE PROBES

The following instructions are intended exclusively

for

authorised service personnel

.

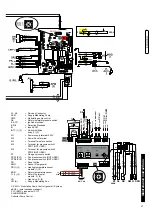

1) Maximum output adjustment

- Operate the boiler in “calibration” mode at MAXIMUM OUT-

PUT (see 3.11.1)

- Once the burner is on check

that the CO

2

“MAXIMUM” value corresponds to that indicated

in the table “NOZZLES - PRESSURE”.

- if it does not correspond, correct it by turning the screw

“S”

CLOCKWISE to decrease it, ANTICLOCKWISE to increase

it.

3.12 - ADJUSTING THE BURNER

2) Minimum output adjustment

- Operate the boiler in “calibration” mode at MINIMUM OUTPUT

(see 3.11.1)

- Once the burner is on check that the CO

2

“MINIMUM” value

corresponds to that indicated in the table “NOZZLES - PRES

-

SURE”.

- Correct it if needed by turning (with a screwdriver) the screw

“R”;

CLOCKWISE to increase it, ANTICLOCKWISE to de-

crease it

(S)

ADJUSTMENT SCREW

MAXIMUM OUTPUT

(R)

ADJUSTMENT SCREW

MINIMUM OUTPUT

- Remove the cap and insert the CO2 analysis probe in the

flue gas sample point of the intake/exhaust terminal, see

chap. 3.11.2.

All boilers leave the factory already calibrated and

tested, however in the event the gas valve (BODY

1, BODY 2) recalibration are required:

To determine the combustion efficiency

one must make the following measurements:

- measurement of the combustion air temperature

- measurement of the flue gas temperature and content of

CO

2

taken in the relevant hole

2

.

Take the measurements with the generator in steady state

conditions (see par. 3.11.1).

Flue

gas

probe