UNIBLOC-PD Operation & Service Manual: PD200-576 35

4.8 Troubleshooting

PROBLEM

POSSIBLE CAUSE

SOLUTION

A. No flow, but pump turns; pump

does not prime

1. Motor turning in wrong

direction

2. Air pocket in pipe or pump.

3. NPSHA too low.

4. Pump runs too slow.

5. Viscosity too high.

6. Obstruction in discharge piping,

valve closed.

1. Reverse motor.

2. Fill pipe and pump with liquid.

Check pipe fittings for leaks.

3. Increase suction pipe diameter or

shorten suction pipe length.

Decrease pump speed. Raise feed

tank or supply liquid level.

4. Increase speed.

5. Lower viscosity if possible.

6. Remove obstruction, open valve.

B. Capacity too low, but pump turns

1. NPSHA too low.

2. Pump runs too slow.

3. Increased slip in pump.

4. Discharge pressure higher than

expected.

5. Front cover not tight.

6. O-ring installed in front cover is

too thick.

1. See A-3

2. Increase speed.

3. Check rotor clearances; replace

worn parts if necessary.

4. Check discharge piping for

closed valves or obstructions. In-

crease pump speed BUT DO NOT

EXCEED PRESSURE LIMITS

OF PUMP. Increase discharge

pipe size. Increase pump size.

5. Tighten cover nuts to torques

specified in section 5.3.

6. Replace front cover o-ring with

correct size.

C. Pump is noisy, cavitating

1. Collapsed suction hose.

2. Liquid temperature too high.

3. Speed too high.

4. Viscosity higher than Expectected

5. NPSHA too low.

6. Suction side valve closed

1. Use reinforced hose or rigid

piping.

2. Reduce speed, increase NPSHA.

3. Decrease speed.

4. Decrease speed, increase pump

size.

5. See A-3.

6. Open valve, check suction side

piping for obstructions

D. Rotors gall, pump seizes

1. Liquid temperature too high.

2. Rotor clearances incorrect.

3. Loose rotor bolts/housing studs.

4. Bearings worn.

5. Gears worn.

6. Foreign particles in pump.

7. Particles in product too large.

8. Discharge pressure too high.

1. Lower temperature or increase

Rotor clearances.

2. Adjust to factory recommended

clearances.

3. Tighten or replace if necessary.

4. Replace bearings.

5. Replace gears.

6. Install suction side filter.

7. Increase rotor clearances. Use

plastic rotors. Increase pump size.

8. See B-4.

Содержание 54001010P20H6010T12E

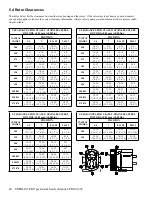

Страница 42: ...42 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Страница 43: ...UNIBLOC PD Operation Service Manual PD200 576 43 UNIBLOC PUMP ...

Страница 44: ...44 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Страница 45: ...UNIBLOC PD Operation Service Manual PD200 576 45 UNIBLOC PUMP ...

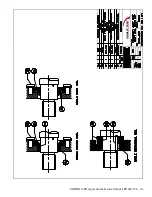

Страница 46: ...46 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Страница 47: ...UNIBLOC PD Operation Service Manual PD200 576 47 UNIBLOC PUMP ...

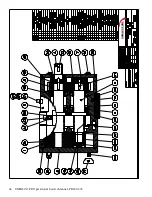

Страница 48: ...48 UNIBLOC PD Operation Service Manual PD200 576 UNIBLOC PUMP ...

Страница 49: ...UNIBLOC PD Operation Service Manual PD200 576 49 UNIBLOC PUMP ...

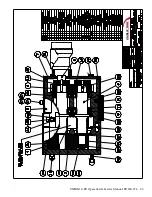

Страница 50: ...50 UNIBLOC PD Operation Service Manual PD200 576 3 ...

Страница 51: ......

Страница 52: ......