12

GENERAL MAINTENANCE

PRE TEST CHECKLIST

SETTING INLET TEMPERATURE

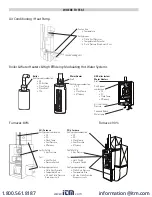

ANALYZER CONNECTIONS

EMPTYING & CLEANING THE IN-LINE WATER TRAP

CHANGING THE PARTICLE FILTER

• Re-certify your instrument annually to ensure it meets original performance specifications

• Keep your instrument dry . If it gets wet, wipe dry immediately . Liquids can degrade electronic circuits

• Whenever practical, keep the instrument away from dust and dirt that can cause premature wear

• Although your instrument is built to withstand the rigors of daily use, it can be damaged by severe impacts . Use reasonable caution

when using and storing the meter

• Turn on and zero the analyzer with out the flue probe connected to use ambient temperature

• Connect flue probe thermocouple to T1 during zero countdown to store probe tip temperature as inlet (ducted system)

The in-line water trap should be checked and emptied on a regular basis . Water vapor will condense in

the probe line, which may cause the water trap to fill suddenly if the probe is moved . Care should be

taken at all times .

Carefully remove the rubber plug from the bottom of the water-trap housing . Dispose of the condensate

in a suitable drain, care must be taken as it could be acidic . If condensate spills onto the skin or clothing,

clean off immediately using fresh water, seek medical advice if problems occur . Ensure plug is replaced

before performing combustion tests . Note: O2 reading will be high if the Water Trap Plug is not in place .

This is a very important part of the analyzer and should be changed regularly . It prevents dust and dirt

particles from entering the pump and sensors that will cause damage . The filter MUST be changed when

it appears discolored on the inner surface .

Remove water-trap assembly from the analyzer as shown above . Remove the filter and plastic holder

from the housing . Discard the filter element but keep the holder to fit to the new filter . Clean the inside

of the filter housing with a suitable soft cloth . Fit the holder onto the new filter element and then insert

into the housing . Refit the housing onto the analyzer .

• Clean particle filter

• Water trap and probe line are empty of water

• Power on and zero

• All hose and thermocouple connections are properly secured

• Flue gas probe is sampling ambient FRESH air

• Water trap is fitted correctly to the instrument

• Flue temperature plug is connected

WARNING!

Turning the pump off while the probe is in the flue will leave toxic gases inside

the analyzer . Once data has been printed or copied it is advisable to purge the

unit with fresh air as soon as possible . To do this remove the probe from the flue

and turn ON the pump . Always allow the readings to return to zero (20 .9 for O2)

prior to shutting the unit off . The meter will not switch off until the CO reading

is below 20 ppm .

WARNING!

The probe will be hot from flue gases . Remove the probe from the flue and allow

it to cool naturally . Do not immerse the probe in water, as this will be drawn into

the analyzer and damage the pump and sensors . Once the probe is removed from

the flue and the readings have returned to ambient levels hold down “On/Off”

and switch off the analyzer . The instrument will count down from 30 to switch

off . If you pressed “On/Off“ by mistake, pressing “Send“ will return you to normal

operation .

NOTE: Take care when inserting

the temperature probes as the

pins are polarized . Insert with the

smaller pin (+) to the right .

NOTE: Do not insert anything

into programming port.

www.

.com

1.800.561.8187