IM800-06

www.ueonline.com

800 Series

Indicating Temperature Controls

Types 800, T800, 802

Please refer to IMT120 for Explosion Proof Types

820E and 822E

U N I T E D E L E C T R I C

C O N T R O L S

Installation and Maintenance

Instructions

IM800-06

GENERAL

Temperature variations are sensed by a liquid filled sensing bulb which

hydraulically transmits motion through a mechanism which rotates the indi-

cating pointer and actuates precision snap-acting switch(es). Control set

point(s) are varied by turning the external adjustment knob(s), according to

procedures outlined (See Part II - Adjustments). Thermometer type T800

provides temperature indication only with no snap-acting switch.

MAXIMUM TEMPERATURE* STATED IN LITERATURE AND ON

NAMEPLATE MUST NEVER BE EXCEEDED, EVEN BY SURGES IN

THE SYSTEM. OCCASIONAL OPERATION OF UNIT UP TO MAX.

TEMPERATURE IS ACCEPTABLE (E.G., START-UP, TESTING). CONTINUOUS

OPERATION SHOULD BE RESTRICTED TO THE DESIGNATED ADJUSTABLE

RANGE.

Maximum Temperature - the highest temperature to which a sensing element

may be occasionally operated at, without adversely affecting set point calibra-

tion and repeatability.

Please refer to product bulletins for product specifications. Product bulletins

may be found at www.ueonline.com.

Part I -Installation

Tools Needed

Phillips screwdriver to secure

customer supplied screws

5/64” Allen Wrench

INSTALL UNIT WHERE SHOCk, VIBRATION AND TEMPERATURE FLUC-

TUATIONS ARE MINIMAL. DO NOT MOUNT UNIT IN AMBIENT TEMPERA-

TURES EXCEEDING PUBLISHED LIMITS. ORIENT UNIT SO THAT MOIS-

TURE IS PREVENTED FROM ENTERING THE ENCLOSURE.

PREVENTATIVE MAINTENANCE / PERIODIC TESTING (6 MONTHS OR SOONER

AS DICTATED BY THE ENVIRONMENT) IS NECESSARY TO ENSURE OPERATION

OF THE PRODUCT TO SPECIFICATION. LUBRICATE ALL PIVOT POINTS AND

MOVING PARTS, TO PREVENT CORROSION, WITH COMPATIBLE DRY LUBRICANTS OR LIGHT

GREASE.

When mounting 800 or 802 type controls, it may be necessary to remove

adjustment knob and front cover. The knob is secured with a 5/64” Allen

Setscrew. The cover is secured by four phillips screws at the corners.

MouNTING

The controller may be mounted in any position to either a surface or panel

(1/4” thick maximum). Locate it where vibration, shock and ambient tempera-

ture fluctuations are minimal. It is recommended that mounting the unit with

the conduit connection on the top be avoided.

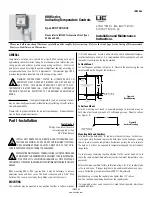

To Flush Mount

Cut out the panel as shown in Figure 1A. Mount to the panel using the two

holes located on the flange of the enclosure.

To Surface Mount

Attach 2 mounting ears found in separate package to recessed areas on

back side of enclosure by means of 2 self-tapping screws. Mount to surface

per Figure 1B.

Mounting Bulb and Capillary

Fully immerse the bulb and 6” of capillary in the control zone. For best con-

trol it is generally desirable to place the bulb close to the heating or cooling

source in order to sense temperature fluctuations quickly. Be sure to locate

the bulb so it will not be exposed to temperature beyond the instruments

range limits.

Try to place any remaining capillary adjacent to the control head so it will

sense the same ambient temperatures (control is ambient temperature com-

pensated).

Unless otherwise specified, factory calibration, allows for 6” of capillary tube

in the control zone. If longer lengths are required recalibration may be nec-

essary. Follow the procedure outlined in PART II - Adjustments.

Avoid bending or coiling the capillary tube tighter than 1/2” radius.

Exercise caution when making bends near the capillary ends.

If a separable well or union connector is used follow separate instructions

included with them.

Please read all instructional literature carefully and thoroughly before starting. Refer to the final page for the listing of Recommended

Practices, Liabilities and Warranties.

CLEARANCE FOR #8

SCREW - (2) PLACES

Figure 1A -

Flush Mounting

Clearance for #10

screw - (2) places

Figure 1B -

Surface Mounting