12

Installation and putting into operation

printed: 02/2015 Subject to change!

TopLineUserManualHT.docx

4

Installation and putting into operation

In general all Hot Cabinets will be packed for safe transport after the final control in

order to reach you properly. Nevertheless we ask you to have a look at the machine

on arrival to detect any transport damages if there are any.

Note!

Visible damages have to be reported immediately!

4.1 Unwrapping

•

Open the carton and take out the wrappingmaterial carefully.

•

Take care that the delivery is complete (see attached freight papers).

4.2 Installation

Place the Hot Cabinet in the desired location. Make sure, that is is good visible for

your customer to ensure good foodpresentation and successfull sales.

Take care of the following points:

The Hot Cabinet has to be placed on a horizontal level. Use a spirit level if neces-

sary.

Take care that both sides have at least 10cm clear space to enable cleaning of

the sideglasses.

There has to be enough free space to load, unload, clean and maintain the unit.

The machine has to be placed so that the complete area around it can be cleaned

easily.

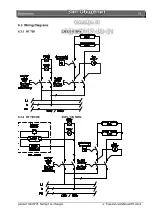

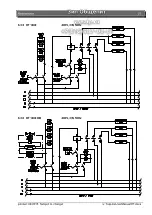

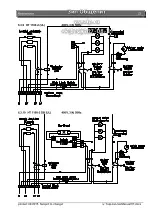

4.3 Electrical connection

Note!

In general, only service technicians of the company: UBERT GASTRO-

TECHNIK GMBH or service technicians of your responsible service partner are al-

lowed to perform el. connection and other service! All national and lokal rules and

regulations concerning electricity, fireprotection and the like have to be concidered.

During any servicing, take care that the unit is disconnected from the mains! Not pay-

ing attention may result in injury!

Please learn the electrical and technical data of your unit from the nameplate.

Check whether your lokal electrical power supply is in accordance with the values on the name

plate.

Make sure the supply cable is protected as listed below:

(3- wire, min. cross-section 1,5

) separatly with 16 Amps.

UL-versions: For supply wire gauge note the specification as shown to the terminal block inside

the unit.

The power supply needs to be manufactured from heat resistant, flexible cable. It is to be rou ted

to prevent any contact to hot parts.

The unit is to be connected to the power supply either by means of an appropriate plug or if con-

nected permanently, a switch (interupting all poles) is to be provided. In case of an emergancy

the power supply must be interuptable immediately.

For further information please see the wiring diagram (below).

Note!

After finishing any installationwork, maintainance or repair check whether the ground

wires are connected properly to the casing.

Содержание HT Series

Страница 1: ...User Manual HOT DISPLAY CABINET HT Series...

Страница 2: ......

Страница 11: ...Introduction 11 printed 02 2015 Subject to change TopLineUserManualHT docx all types 70 dB A...

Страница 28: ...28 Maintenance printed 02 2015 Subject to change TopLineUserManualHT docx...

Страница 30: ...30 Maintenance printed 02 2015 Subject to change TopLineUserManualHT docx...

Страница 32: ...32 Maintenance printed 02 2015 Subject to change TopLineUserManualHT docx 6 5 Declaration Of Conformity...