10

SOLUS

®

500R - 56041970

6/07

INSTRUCTIONS FOR USE

A - ENGLISH

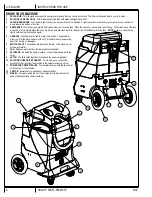

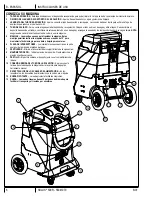

AFTER USING THE MACHINE

1

To empty the Holding Tank, vacuum out all unused solution into the recovery tank using the vacuum hose. Rinse the tank with clean water.

2

Turn all the Power Switches

(A, C, E, F & H)

to OFF (O). Unplug the Power Cords.

3

To empty the recovery tank, loosen the Velcro strap retaining the Recovery Tank Drain Hose

(4)

. Direct the hose to a designated waste

water “DISPOSAL SITE” and remove the plug (hold the end of the hose above the water level in the tank to avoid sudden, uncontrolled

fl

ow

of waste water). Rinse the tank with clean water. Inspect the drain hose; replace if kinked or damaged.

4

Remove the pre

fi

lter bag from the Vacuum Inlet

(3)

. Empty and rinse the pre

fi

lter and reinstall.

5

Disconnect the solution and vacuum hoses from the machine, at the Solution Hose Quick Connect

(10)

and Vacuum Hose Connection

(3)

respectively. Flush the vacuum hose with warm water to wash any debris out of the vacuum hose and cleaning tool. Inspect them for

damage.

6

Wipe the machine with a damp cloth. Do not use abrasive chemicals or solvents.

7

Perform any required maintenance before storage.

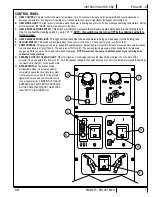

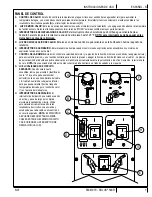

MAINTENANCE SCHEDULE

MAINTENANCE ITEM

Daily

Weekly

Yearly

Check / Clean Tanks & Hoses

•

Check / Clean Recovery Tank Shut-Off Float

•

Clean Extraction Wand/Tool

•

Inspect & Clean Solution Filters

•

Check Carbon Brushes

•

IMPORTANT!

Motor damage resulting from failure to service the carbon brushes is not covered under warranty. See the Limited

Warranty Statement.

8

Store the machine indoors in a clean, dry place with the recovery tank lid open. Keep from freezing.

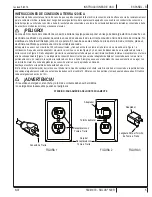

POWER CORD MAINTENANCE

Once a week (or more often if necessary), check the power cords for cracked or damaged insulation, exposed wires in the cord or plug, and

damaged or missing ground pin. Repair or replace damaged cord or plug

immediately

.

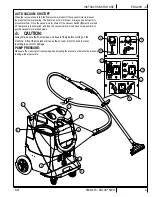

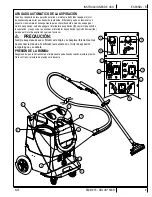

MAINTENANCE:

For optimum performance,

fl

ush the machine with clear water at the end of each working day. Once a month, minimum, run a

fl

ushing compound

through the machine to break up any mineral or chemical build-up that may have formed. The vacuum motor, pump motors, and the pumps do not

require any scheduled maintenance; however, the motors may require replacement brushes after 1000 - 1500 hours, and the pump and bypass

valve may require rebuild kits after 500 -1500 hours (refer to machine part list for numbers). Clean the body with an all purpose detergent, and

protect it with an automobile interior polish. Lubricate the wheels, castors, and quick disconnects with an all purpose silicone spray.