24

15. Fill boiler to normal water line. Follow Operating

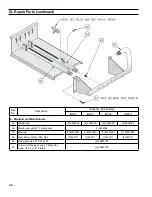

Instructions to place boiler in operation. See Figure

21.

16. Operate boiler for at least 30 minutes after

condensate begins to run hot. Follow instructions

TO TURN OFF GAS TO APPLIANCE. See Figure

21.

17. Close all radiator valves. Remove all supply main

air valves. Plug openings in supply main.

18. Drain approximately 5 gallons of boiler water into

container. Mix in recommended boil-out

compound.

19. Remove safety valve. Pour recommended compound

into boiler through safety valve opening. Reinstall

safety valve in Tapping "E" with spindle in vertical

position.

20. Follow Operating Instructions to place boiler in

operation. See Figure 21. Slowly feed water to

boiler. Water will rise slowly into supply main and

back through return main. Adjust flow to maintain

approximately 180°F water from return main hose.

Continue until water runs clear from hose for at

least 30 minutes.

21. Turn off water to boiler. Continue to operate until

excess water is removed from boiler and system (by

steaming) and boiler water reaches normal

waterline.

22. Follow instructions TO TURN OFF GAS TO

APPLIANCE. See Figure 21. Open all radiator

valves. Reinstall all supply main air valves. Open

gate valve in Hartford Loop.

23. Allow boiler to cool until crown sheet is no longer

too hot to touch. Close drain valves at boiler and in

return main. Fill boiler slowly to normal waterline.

24. Follow Operating Instructions to place boiler in

operation. See Figure 21. Allow boiler to steam for

10 minutes. Drain one quart of water from lower

Gauge Glass fitting.

25. Drain second quart sample from lower Gauge Glass

fitting. If sample is not clear, repeat cycle of draining

boiler and return main and refilling boiler until

sample is clear.

26. If after normal operation boiler water becomes dirty

from additional system piping sediment returning to

boiler.

a. Complete steps 12 through 25.

b. Complete steps 1 through 11.

P.

Add Boiler Water Treatment

1. Remove safety valve.

2. Pour recommended compound into boiler through

safety valve opening.

3. Reinstall safety valve in Tapping "E" with spindle in

vertical position.

4. Follow Operating Instructions to place boiler in

operation. See Figure 21.

5. Boil water or heat water to 180°F.

6. Test the pH of the water in the system. This can

easily be done by drawing a small sample of boiler

water and testing with Hydrion paper which is used

in the same manner as litmus paper, except it gives

specific readings. A color chart on the side of the

small Hydrion dispenser gives the reading in pH.

Hydrion paper is inexpensive and obtainable from

any chemical supply house or through your local

druggist. The pH should be higher than 7 but lower

than 11. Add recommended water treatment

chemicals, if necessary, to bring the pH within the

specified range. With this lower level of protection,

care must be exercised to eliminate all of the free

oxygen in the system.

7. Boiler is now ready to be put into service.

Q.

Review User's Information Manual

and system

operation with owner or operator.

VII. System Start-up (continued)

Содержание INDEPENDENCE IN3PV

Страница 7: ...7 Figure 4 Steam Piping IN3PV Figure 3 Trim Installation III Steam Piping and Trim continued...

Страница 29: ...29 SERVICE RECORD DATE SERVICE PERFORMED...

Страница 42: ...42 SERVICE RECORD DATE SERVICE PERFORMED...

Страница 43: ...43 SERVICE RECORD DATE SERVICE PERFORMED...

Страница 44: ...44 U S Boiler Company Inc P O Box 3020 Lancaster PA 17604 1 888 432 8887 www usboiler net...