TFP852

Page 3 of 6

Corrosion Resistance

It is recommended that the Tunnel

Operator be consulted with respect

to the suitability of the materials of

construction and finish for any given

corrosive environment. The effects of

ambient temperature, concentration of

chemicals, and gas/chemical velocity,

should be considered, at a minimum,

along with the corrosive nature to which

the nozzles may be exposed.

The pipe, fittings, hangers, and hanger

components must be suitable for use in

the application environment.

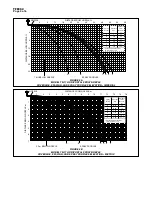

Obstructions

The maximum allowable vertical and

horizontal distance that the bottom of

an obstruction can be away from the

Model TN-17 Nozzle is provided in

Graph A.

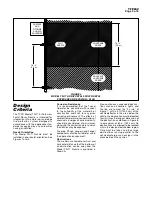

Design

Criteria

The TYCO Model TN-17 K=16.8 Hori-

zontal Spray Nozzle is intended for

integration into a water spray, deluge

fire protection system designed in

accordance with the applicable stan-

dards recognized by any authorities

having jurisdiction.

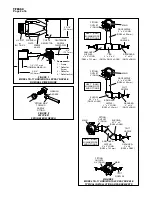

Nozzle Orientation

The Model TN-17 Nozzle must be

installed in a horizontal orientation. See

Figures 1 and 3.

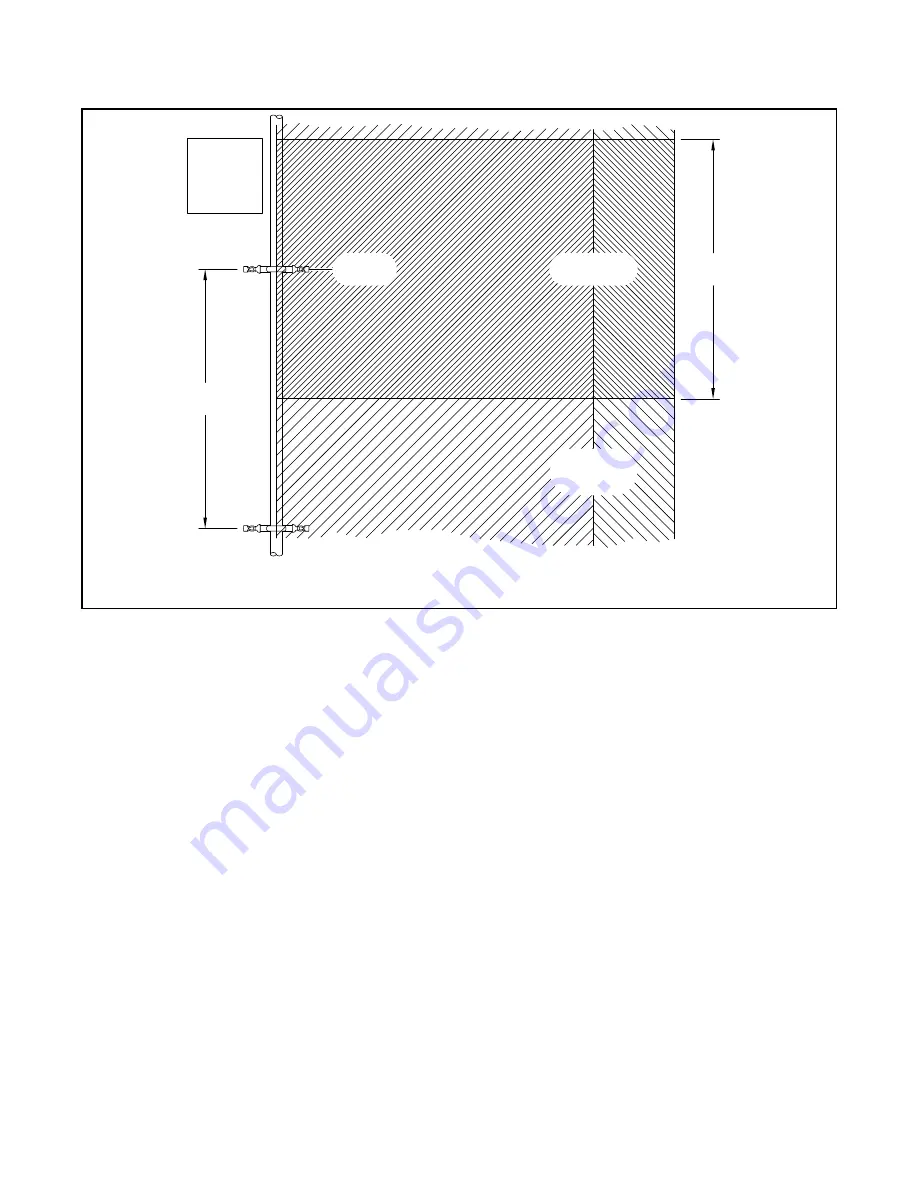

Non-continuous suspended obstruc-

tions such as air handlers, lights, and

the like are to meet the “4x rule” of

Figure 7; within 5 ft (152,4 cm) of the

nozzle deflector in the area below the

nozzle, the obstruction must be located

four (4) times the longest dimension of

the obstruction as defined in Figure 6,

to a maximum of 60 in. (152,4 cm). No

obstructions are allowed to be located

within the designated shaded region.

Care must be taken to place large

obstructions running parallel to the

nozzle discharge, such as signs, in the

areas between the nozzles.

TN-17

NOZZLE

16'-4"

(5,0 m)

NOZZLES

AND

FITTINGS

SHOWN

ENLARGED

16'-4"

(5,0 m)

COVERAGE

AREAS

ADJACENT

COVERAGE

AREAS

FIGURE 4

MODEL TN-17 HORIZONTAL SPRAY NOZZLE

COVERAGE AND SPACING – PLAN