408-1537

Hand Tool Assembly 59282

3 of 4

Rev B

Tyco Electronics Corporation

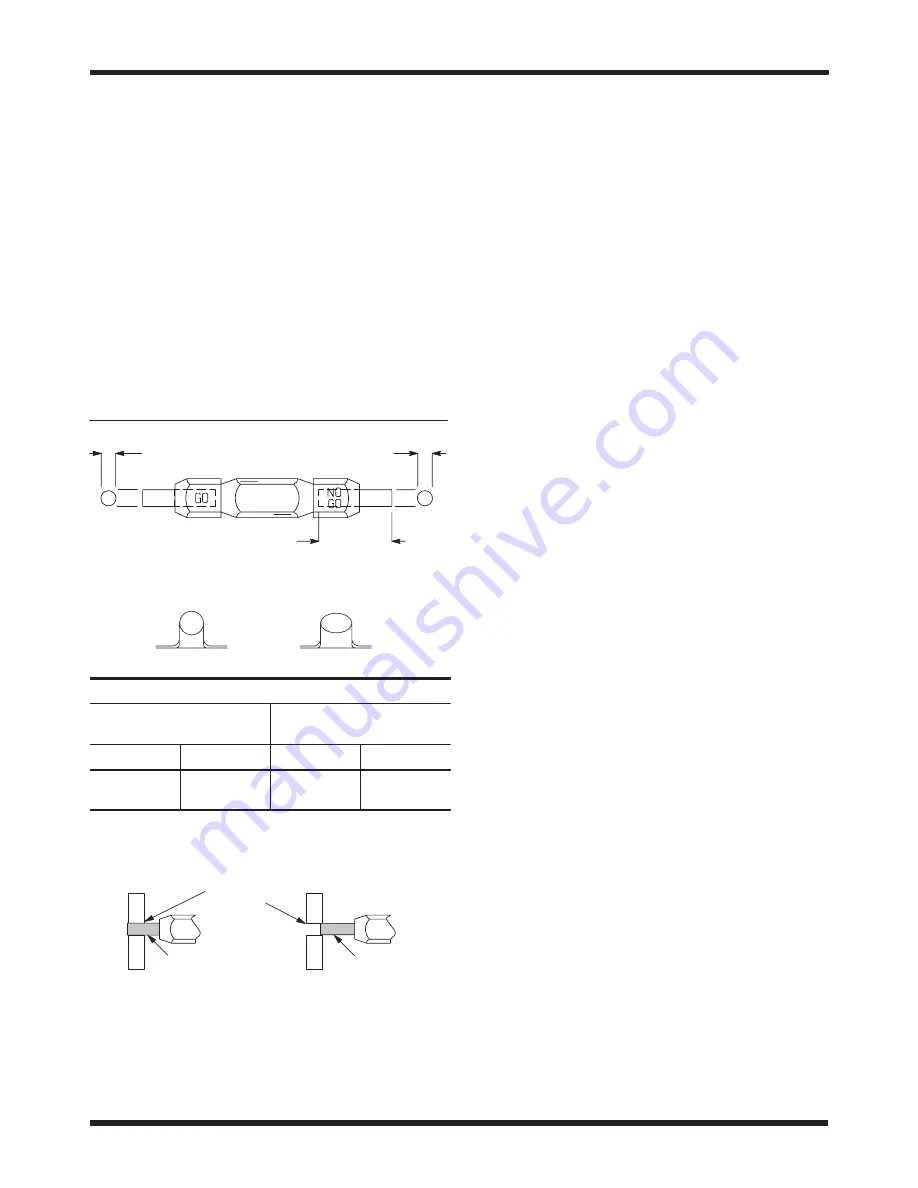

straight into the chamber, but do not force it. The

GO element must pass completely through the

chamber.

5. Align the NO–GO element and try to insert it

straight into the same crimping chamber section.

The NO–GO element may begin entry as shown in

Figure 4, but must not pass through the chamber.

If the crimping chamber conforms to the gage

inspection, the tool may be considered dimensionally

correct and should be lubricated with a THIN coat of

any good SAE 20 motor oil. If the crimping chamber

does NOT conform to the gage inspection, the tool

must be returned for further evaluation and repair.

See Section 5, REPLACEMENT AND REPAIR.

For additional information regarding the use of a plug

gage, refer to Instruction Sheet 408–7424.

NO-GO Diameter

GO Diameter

Suggested Plug Gage Design

50.8 [2.0] Min Typ

Die Closure Configuration

Insulation Barrel Crimp

Wire Barrel Crimp

GAGE ELEMENT DIAMETER

Insulation Barrel Section of

Crimping Chamber

Wire Barrel Section of

Crimping Chamber

GO

NO-GO

GO

NO-GO

4.064-4.072

[.1600-.1603]

4.265-4.267

[.1679-.1680]

3.353-3.360

[.1320-.1323]

3.503-3.505

[.1379-.1380]

Figure 5

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

ÉÉ

É

É

É

É

É

É

GO Element

NO-GO Element

GO element must pass

completely through the

crimping chamber.

NO-GO element may enter

partially, but must not pass

completely through the

crimping chamber.

Crimping

Chamber

Inspection of Crimping Chamber

4.3. CERTI-CRIMP Hand Tool Ratchet Control

Inspection

Check the ratchet to ensure that the ratchet does not

release prematurely, allowing the dies to open before

they have fully bottomed. Proceed as follows:

1. Remove traces of oil or dirt from the bottoming

surfaces of the dies.

2. Obtain a 0.025 mm [.001 in.] shim that is

suitable for checking the clearance between the

bottoming surfaces of the dies.

3. Select a splice and

maximum size wire for the

splice.

4. Position the splice in the crimping chamber

according to Section 3, CRIMPING PROCEDURE.

Holding the wire in place, squeeze the tool handles

together until the ratchet releases. Hold the tool

handles in this position, maintaining just enough

pressure to keep the dies closed.

5. Check the clearance between the bottoming

surfaces of the dies. If the clearance is 0.025 mm

[.001 in.] or less, the ratchet is satisfactory. If

clearance exceeds 0.025 mm [.001 in.], the ratchet

is out of adjustment and must be repaired. See

Section 5, REPLACEMENT AND REPAIR.

5. REPLACEMENT AND REPAIR

Customer–replaceable parts are listed in Figure 6.

A complete inventory should be stocked and

controlled to prevent lost time when replacement of

parts is necessary. Parts other than those listed

should be replaced by Tyco Electronics to ensure

quality and reliability. Order replacement parts

through your Tyco Electronics Representative, or call

1–800–526–5142, or send a facsimile of your

purchase order to 717–986–7605, or write to:

CUSTOMER SERVICE (038–035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105–3608

For customer repair service, contact a Tyco

Electronics Representative at 1–800–526–5136.

6. REVISION SUMMARY

S

Updated document to corporate requirements

S

Changed dimensions in table in Figure 5