TW-SP245 MANUAL

state: 14.03.2019

page

10

of

12

P9

U-RING

1

P36

U-RING LIMIT

1

P10

PUMP CORE SEAT

1

P37

STEEL BALL

3

P11

O-RING

1

P38

PUMP ASSY

1

P12

WASHER

2

P39

SCREWS

1

P13

HANDLE CONNECTOR

1

P40

WASHER

2

P14

SCREWS

1

P41

WASHER

2

P15

AIR PUMP

1

P42

SCREWS

2

P16

STEEL BALL

3

P43

AIR HOSE

1

P17

SCREWS

5

P44

AIR VALVE

1

P18

WASHER

5

P45

CONNECTOR

1

P19

SPRING

3

P46

R PIN

1

P20

SPRING

2

P47

STEEL BALL

2

P21

VALVE SEAT

2

P48

NYLON RING

1

P22

STEEL BALL SEAT

2

P49

CONNECTOR

1

P23

STEEL BALL SEAT

1

P50

O-RING

1

P24

SPRING

2

P51

HANDLE

1

P25

SPRING

1

P52

HOSE

1

P26

SCREWS

2

P53

CONNECTOR

1

P27

O-RING

3

Part No. Description

Qty.

Part No.

Description

Qty.

R01

PIN

2

R10

VALVE ROD

1

R02

RAM

1

R11

NYLON RING

1

R03

SPRING

2

R12

SCREW

1

R04

CONNECT

1

R13

PISTON

1

R05

O RING

2

R14

NUT

1

R06

SEAL RING

1

R15

O RING

1

R07

PISTON CAP

1

R16

SPRING PLATE

1

R08

SPRING

1

R17

Serrated

Saddle

1

R09

BALL

1

R18

SCREW

1

Содержание TWSP245

Страница 1: ......

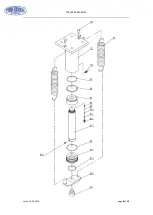

Страница 6: ...TW SP245 MANUAL state 14 03 2019 page 6 of 12 5 Spare parts 5 1 Exploded views ...

Страница 7: ...TW SP245 MANUAL state 14 03 2019 page 7 of 12 ...

Страница 8: ...TW SP245 MANUAL state 14 03 2019 page 8 of 12 ...

Страница 11: ...TW SP245 MANUAL state 14 03 2019 page 11 of 12 ...

Страница 12: ...TW SP245 MANUAL state 14 03 2019 page 12 of 12 ...