20 |E

t

wall

®

Compact32

stationary | User Manual Rev. 1.0

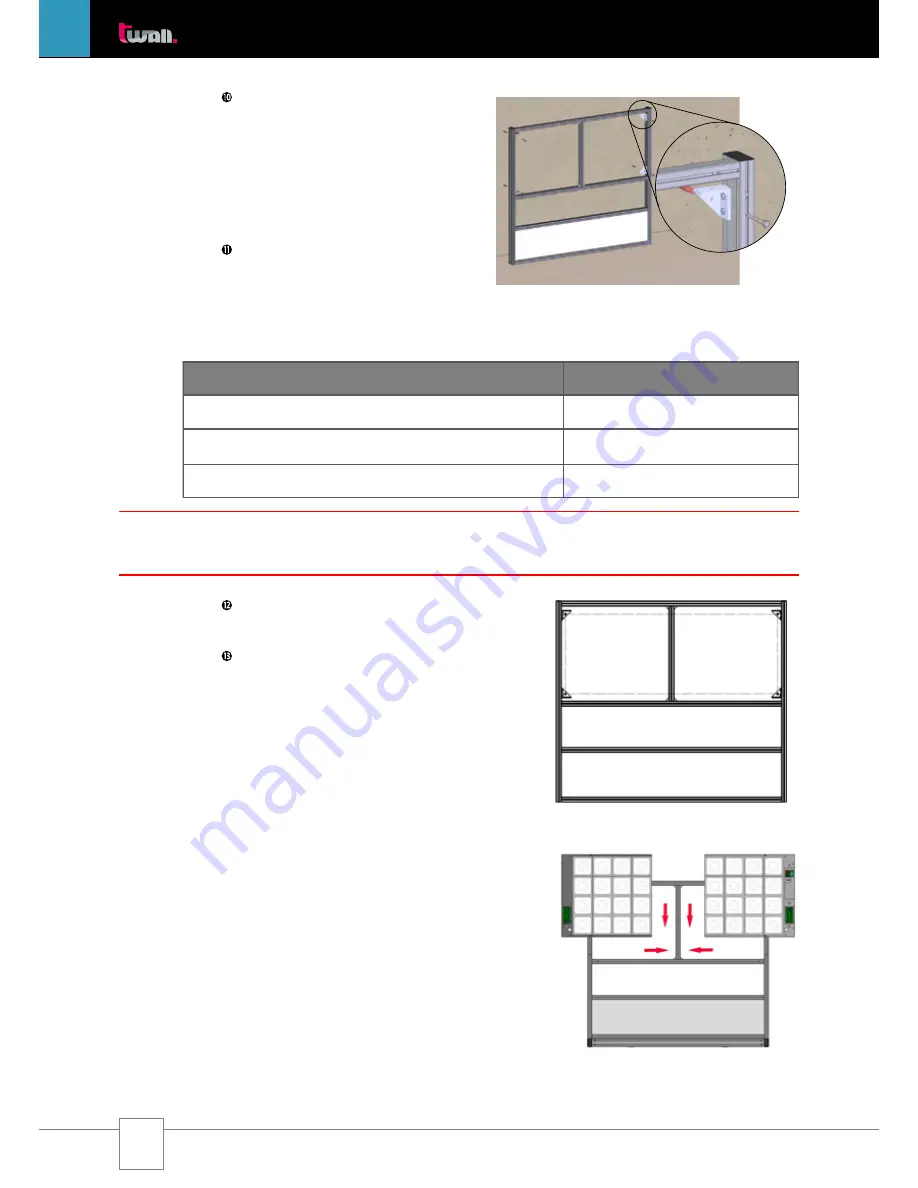

Step

10

The brackets

A2f

are now also

attached to the top guide grooves on the

insides of the side stands

(Fig. 3.2-12)

. To

do this, please use 2 M8x20

Verbus-Ripp

screws

per bracket and tighten these firmly

(approx. 25 Nm).

IV. Assembling the universal wall:

Step

11

To be able to mount the universal

wall to a wall, you need a hammer drill, a

12 mm

impact drilling machine and

appropriate protective gear. The following

boreholes must be made in the wall:

Distances at the wall

t

wall

®

Compact32

stationary

Floor to centre of bottom borehole:

950 mm

Centre of bottom borehole to centre of top borehole

700 mm

Horizontal distance between borehole centres

1863 mm

Step

12

Insert the dowels supplied into the

boreholes in the wall.

Step

13

Lift the universal wall

A2

(Fig.

3.2-13)

at the top end (near the protective

cover) and place it straightened with the

bottom part against the wall. Now attach

the universal wall frame to the wall while

firmly screwing on the brackets

A2f

with

the 4 hexagon head cap wood screws in

the prepared dowels. When using a torque

spanner, adjust it to 25 Nm.

3.2.2.2 Assembling the touch pads

I. Attaching the touch pads:

(Fig. 3.2-14)

Please proceed exactly as described for the

mobile

t

wall

®

Compact32

(Chapter 3.1.3.3)

.

II. Connecting the touch pads with the

control unit:

Please proceed exactly as described for the

mobile

t

wall

®

Compact32

(Chapter 3.1.3.3)

.

NOTE: At least a double covering must be provided with gypsum cardboard walls. The secureness of the

mounting must be checked on a regular basis.

Fig. 3.2-14

Fig. 3.2-13

Fig. 3.2-12

Содержание Compact 32 stationary

Страница 2: ......