Function 6 - maintenance Cycle activation Control

The “6” key initiates a procedure to set whether the Maintenance Cycle (MC) function is controlled

internally (time accumulates whenever the output is on) or externally (time accumulates only if the

output is on AND the Vehicle Status Input (VSI) input is active). Entry into this mode is signified

by a flash cycle consisting of 1 amber flash followed by 6 red ones. In this mode, the “1” key sets

the MC function control to internal and the “2” key sets it to external. Pressing any other key will

generate an error signal (short then long tone) and the procedure will be aborted, returning you to

supervisor mode. If you are setting the MC control type to internal and/or the Automatic Shut Off

(ASO) function is enabled, a single long flash of the amber “accept” LED will acknowledge the new

setting, and then the unit will go back to supervisor mode. If the ASO function is disabled, and

you are setting the MC control to external, then the unit will automatically go into the VSI

configuration procedure (described on Page 8-9) which must be completed successfully or the

change will not be saved. The default setting for the MC control is internal.

Quick Steps – Function 6

1. While in supervisor mode press 6. Unit will indicate Function 6 configuration mode active.

2. Press 1 to set maintenance counter to internal. Amber LED will indicate acceptance of selection

and unit will return to supervisor mode. Maintenance time will subsequently accumulate when

ever PSL+ activates vehicle.

Or

Press 2 to set maintenance counter to external mode. Maintenance time will Accumulate only when

Vehicle Status Input is active. Note: If Vehicle Status Input was not previously configured, unit will

immediately enter the VSI configuration procedure. (See instruction on Page 8-9 of manual.)

Note: Pressing any other key than “1” or “2” aborts process and returns to supervisor mode.

Function 7 – maintenance Cycle Period

The “7” key initiates a procedure to set the maintenance cycle time. Entry into this mode is

signified by a flash cycle consisting of 1 amber flash followed by 7 red ones. You may change this

setting whether or not the Maintenance Cycle (MC) function is enabled, but if not it won’t have

any effect until that function is enabled. Settings are retained if the MC function is disabled and

enabled at a later date. You may set the maintenance cycle time in one hour increments from

1 to 9999 hours (14 months if running 24/7), but all entries must be 4 digits (Example: 1 hour

= 0001, etc.). Each digit entered will be acknowledged with a short beep. Once the fourth digit

has been entered the unit will save the setting and acknowledge that fact with a long flash of the

amber “accept” LED and then return to the supervisor mode. Pressing the “on” key during this

process will generate an error signal and the procedure will be aborted, returning to supervisor

mode. You may manually abort the process and return to supervisor mode by pressing the “off”

key. A new cycle is started automatically when the MC time is changed.

Quick Steps – Function 7

1. While in supervisor mode press 7. Unit will indicate Function 7 configuration mode active.

2. Enter 4-digit maintenance period in hours (Example: 0510 = 510 hours until maintenance

remainder). Unit saves period upon depression of fourth digit and returns to supervisor mode.

Note: Pressing “off” aborts procedure returning to supervisor mode.

6

Step 1: The unit will indicate entry into this procedure by repeating a display cycle that consists

of 2 amber flashes, 1 red flash, 1 amber flash and a pause. If the signal you are monitoring

is powered by the PSL+ output, you may turn the output on temporarily by pressing the “on”

key. Move the switch or whatever the VSI input is connected to into the position or setting it

will be at when you want the unit to consider the input to be active. For example, if you are

using a seat switch, then you should sit on the seat. When you are sure the input is in the

active state, press any numerical key. The unit will read the input and memorize what it “sees”

and then acknowledge with a long flash of the amber “accept” LED. You may also abort the

configuration procedure by pressing the “off” key if you notice that something isn’t right.

Step 2: After an acknowledge flash the display cycle will change to 3 amber flashes, 1 red flash,

1 amber flash and a pause. At that point you need to change the switch or setting to

the inactive position (in the previous example you would get off of the seat). When you

are sure the input is inactive, press a numerical key. This will prompt the unit to again

read the input. If the unit can detect a difference between the two states, another

acknowledge flash of the “accept” LED will be displayed and then the unit will return

to supervisor mode. If the unit can not detect a difference between the two settings,

then an error signal (short then long tone) will be sounded and the process will be

aborted (including the setting change you were making) and the unit will return to super

visor mode. If the output was turned on in step one; it will automatically go off upon

completion on this procedure.

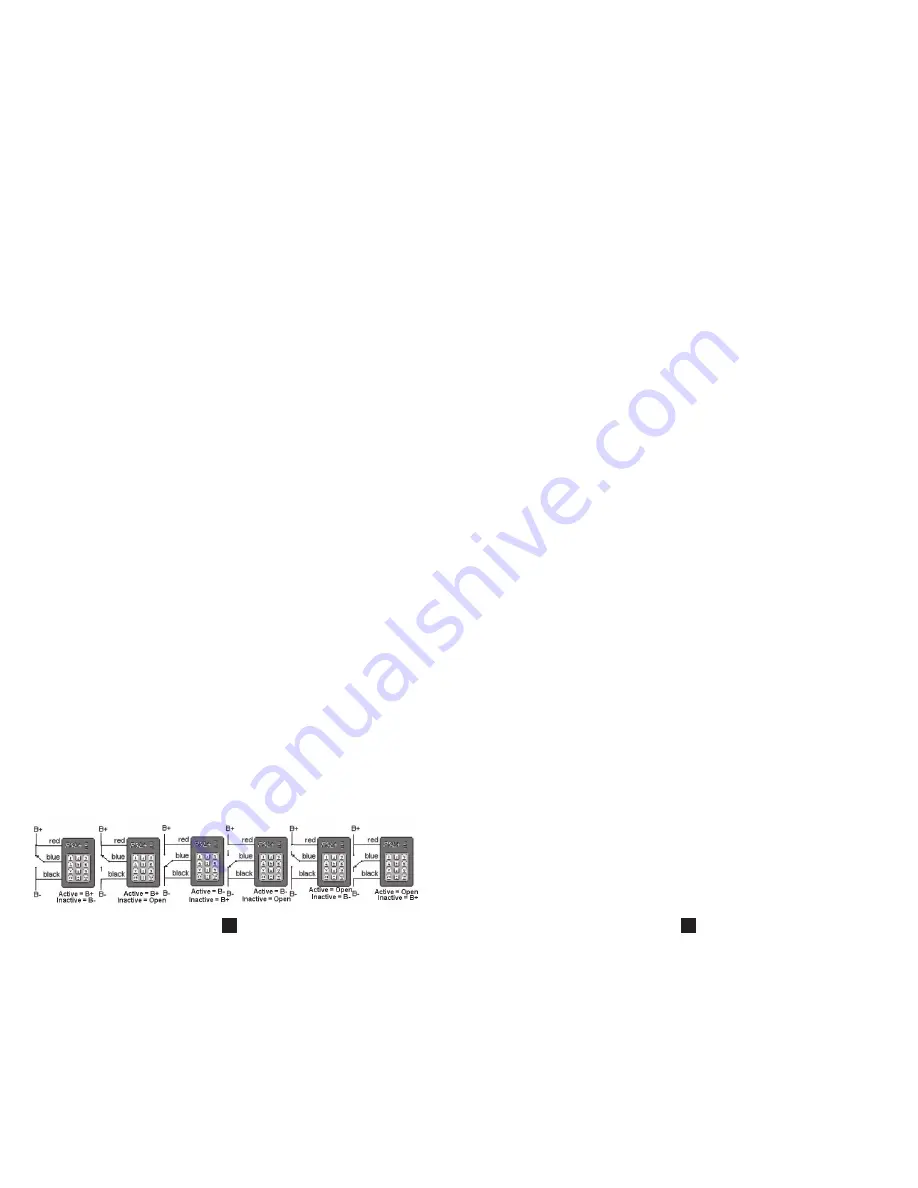

Note: If you are having trouble getting the VSI input to configure properly, consider the following: The VSI

input is designed to detect three states: connected to ground, connected to the positive supply voltage

(B+) or open (not connected to anything). You may use any combination of those three. The VSI input is

not designed to detect voltage level changes within the supply range. Check the wiring to make sure the

input is being driven (or released) into a different one of the three states listed for the active and inac-

tive settings. Many vehicles draw power for such switches from the “key switch” line, so you may need

to turn the PSL+ on during configuration. If the problem still persists, please call for assistance.

Quick Steps – VSI (Vehicle Status Input)

1. Unit flashes 2 amber flashes, 1 red flash, 1 amber flash and a pause to indicate unit is ready to

receive vehicle input.

2. Apply vehicle active signal to blue wire. If this requires the PSL+ output to be on, press the “on” key.

3. Press any numerical key (0-9). Amber LED indicates acceptance of active input.

4. Unit then flashes 3 amber flashes, 1 red flash, 1 amber flash and a pause to indicate unit is ready

to receive vehicle inactive input.

5. Apply vehicle inactive signal to blue wire.

6. Press any numerical key (0-9). Amber LED indicates acceptance of inactive input. Unit returns to

supervisor access mode after inactive input is accepted. If the output was turned on, it will go back off.

acceptable VSI Input States

9