8

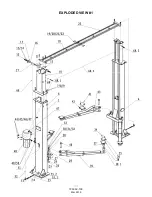

TP9KAC-TUX

Mar 2019

1.

Before proceeding, double check measurements and make certain that the bases of each column are

square and aligned with the chalk line.

2.

Assemble the uprights to the columns. Raise the columns to a vertical position.

(See Fig. 6)

Fig. 6

3.

Using the base plate on the MAIN column as a guide, drill each anchor hole into concrete using a rotary

hammer drill and

3

/

4

” concrete drill-bit. To assure full holding power, do not ream the hole or allow the

drill to wobble.

(See Anchoring Details on Page 4)

4.

After drilling, remove dust thoroughly from each hole using compressed air and/or wire brush. Make

certain that the column remains aligned with the chalk line during this process.

5.

Assemble the washers and nuts on the anchors then tap into each hole with a block of wood or rubber

hammer until the washer rests against the base plate. Be sure that if

shimming is required that enough threads are left exposed.

6.

Using a level, check column plumb for every side

(Fig. 7)

. If shimming is

required, use supplied Shim stock or 3/4

” washers, placing shims as close as

possible to the hole locations. This will prevent bending column bases.

7.

With the shims and anchor bolts in place, tighten by securing the nut to the

base then turning 2-3 full turns clockwise. Ensure anchor bolts are

tightened to a minimum of 130 ft-lbs. of torque. DO NOT use an impact

wrench for this procedure!!

Fig. 7

STEP 5

:

(Installing OFFSIDE COLUMN & OVERHEAD BEAM ASSEMBLY)

NOTE: Install Overhead Beam assembly to top of columns BEFORE drilling anchors for Offside

column. This is to ensure that the Offside column can be properly positioned to be plumb and level.

1.

Raise OFFSIDE column and position at the designated chalk locations, ensuring the

Column

‘upright’

Содержание TP9KAC-TUX

Страница 4: ...TP9KAC TUX Mar 2019...

Страница 20: ...TP9KAC TUX Mar 2019 EXPLODED VIEW 1...

Страница 21: ...TP9KAC TUX Mar 2019 EXPLODED VIEW 2...