11

TP11KC-DX

Jun 2017

3.4

Installation Procedure

1.

Read this manual thoroughly before installing, operating, or maintaining this lift.

2.

Site Evaluation and Lift Location:

A.

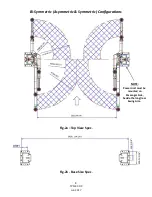

Always use an architect’s plan when provided. Before unpacking the lift entirely, determine if the site is

adequate for the lift model being installed see figures 1 & 2 for typical bay layout and ceiling height

requirements.

B.

Snap chalk lines to identify the lift’s centerline.

C.

Snap a chalk line parallel to the lift’s centerline,

spaced 9.00”

(230 mm) toward the rear of the bay. This line

represents the back edge of the column bases.

D.

Snap chalk lines parallel to the lift’s centerline

spaced 68-7/8”

(1,750 mm)

to the left and 68-7/8”

(1,750 mm)

to the right

. These lines represent the

APPROXIMATE

outside edges of the column bases.

DO NOT USE THESE LINES TO POSITION THE COLUMNS, FOLLOW THE INSTRUCTIONS IN THIS

MANUAL.

3.

Unpack the lift. Remove the swing arms, bolt box, power unit box, and overhead beam.

A.

Save all packing hardware

, as these components

are necessary to complete

the installation.

B.

Remove the 1/2” bolts from the uprights

which hold the two columns together.

C.

Remove the upper column

.

Do not stand the columns up

now but lay the columns with their flat backs on

the floor.

4.

Attach the cylinder mounts (uprights) using 4ea 1/2” x 1-3/4” bolts, washers and nuts provided as shown in figure

4a & 4b.

Fig. 4a

Fig. 4b

Содержание TP11KC-DX

Страница 26: ...26 TP11KC DX Jun 2017 5 Exploded View Parts List...

Страница 32: ...32 TP11KC DX Jun 2017 7 Power Unit Priming...

Страница 33: ...33 TP11KC DX Jun 2017 8 Warranty...