10

FILAMENT SENSOR

The filament sensor detects if the 3D printer has enough filament to print. If it doesn’t, it will stop the printing process

and will make it possible to change it in order to continue the printing process. Please, make sure that your filament

detector is active (check the

Activate Filament Detector table down below).

When there is no filament, a new tab will appear on Repetier Server. You will be able to cancel the print or to turn off

the detection and change the filament. If you decide to change the filament, please follow the steps indicated in the

Filament Changing Process table.

Once you have followed the steps, you can continue with the printing process. By turning off the sensor you will go back

to the main screen, where it is possible to keep interacting with the printer. By selecting the option “Cancel printing”,

the printing will stop.

A blue light will appear on the sensor if the filament has been put on. If the light doesn’t work, please replace the sensor.

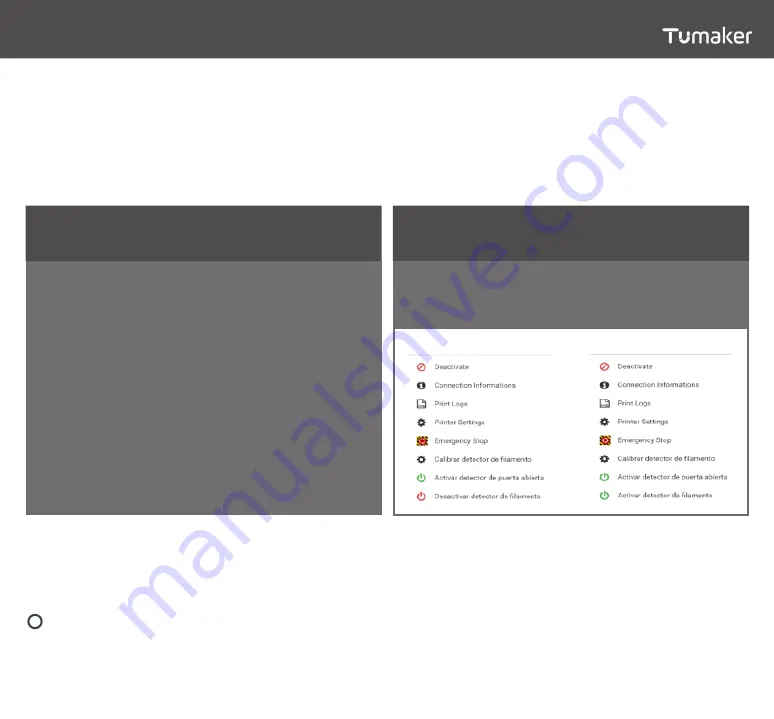

Deactivated

Activated

FILAMENT CHANGING PROCESS

ACTIVATE FILAMENT DETECTOR

1. Go to the Temperature Control on Repetier Server

2. Press “Advanced Options”

3. Press “Activate Filament Detector”

1. The printer detects that there is no filament left

2. The printer will automatically remove the remaining

filament

3. The printer will no longer heat the nozzle

4. Please, remove the spool carefully

5. Select the following material in the menu display

and press “Next Button”

6. Wait until the temperature is stable

7. Introduce the filament on the extruder through the

filament sensor

8. Press “Next Button” and the engines of the extruder

will push the filament to the tip

9. Wait until the engines stop

10. Press “Continue Printing”

IMPORTANT NOTE

Содержание Voladora NX +

Страница 1: ...Warranty Declaration of conformity First steps Included software Voladora NX...

Страница 17: ...17 VoladoraNX...