01/2004 POSIMIN

®

-PHP, -PHPmin

- 13

-

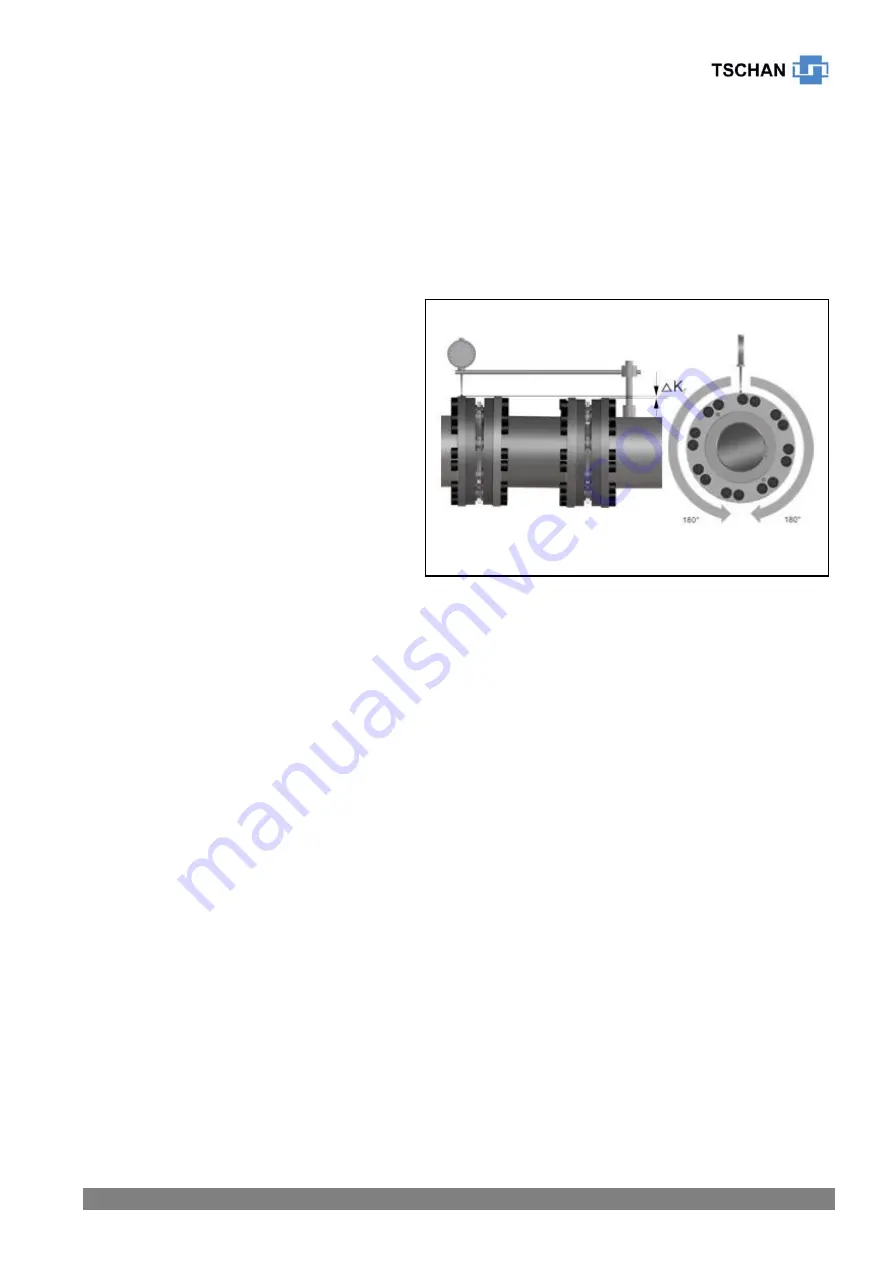

Bild / Fig. 9

If larger axial displacements are to be anticipated during operation, e.g. due to thermal

growth, the coupling can be mounted with axial pre-stretch to account for the expected

growth. This item has to be discussed with TSCHAN GMBH, if it has not been considered

when designing the coupling. In service, the coupling shall run in unconstrained manner with

dimension ‘E’.

7.3 Radial Misalignment

•

Measure one complete revolution. To

this end, turn the dial gauge by 360°.

Determine the largest deviation Kr1

and the smallest deviation Kr2

(Fig. 9).

Calculate the radial misalignment

∆

Kr

= 0,5 x (Kr1 – Kr2). Observe the pre-

ceding sign of the measured values.

•

When aligning, observe the maxi-

mum permissible radial misalignment

in dependence of the centre distance

of the disk packs ‘MLP’.

∆

Kr

max

= MLP/1000 [mm]

•

For verification purposes, this meas-

urement should also be performed on

the second coupling half.

•

The alignment must be corrected in case of any deviations.