3

1.2 Basic Specifications

Thermal transfer and direct thermal printing

High dot density printing; TTP-243(E)/244 Pro series: 203 dots/inch, TTP-342 Pro series: 300

dots/inch

Selectable print speeds (TTP-243 Pro series: 1.5, 2 or 3 ips / TTP-342 Pro series: 1, 1.5 or 2 ips/

TTP-244 Pro series: 2.0, 3.0, 4.0 or 5.0 ips)

Maximum media width up to 4.9" (114mm) for TTP-243 Pro series/ 4.4” (112 mm) for TTP-244 Pro

series

Adjustable label edge guide

International character sets

8 MB SDRAM memory

4 MB FLASH memory

Print area: TTP-243 Pro/243E Pro

:

4.09” W x 90” L

;

TTP-342 Pro

:

4.09”W x 40”L

;

TTP-244 Pro:

4.25”W x 90”L (without any file downloaded in the printer memory)

User selectable bar code ratios and heights

Prints on labels or tickets

Equipped with black mark sensor

Equipped with Real Time Clock (Not available for TTP-243E Pro and TTP-244 Pro)

Comes with self-peeling function (Not available for TTP-243E Pro and TTP-244 Pro)

Label stock and thermal transfer ribbon are easy to install

Internal label print counter

Self test and hex dump mode

Downloadable fonts from label design software

Power

External universal switching power supply

Input: AC 100-240V, 2.5A, 50-60Hz

Output: DC 24V, 2.5A, 60W

Communications Interface:

* RS-232/USB

* RS-232/Centronics (factory option)

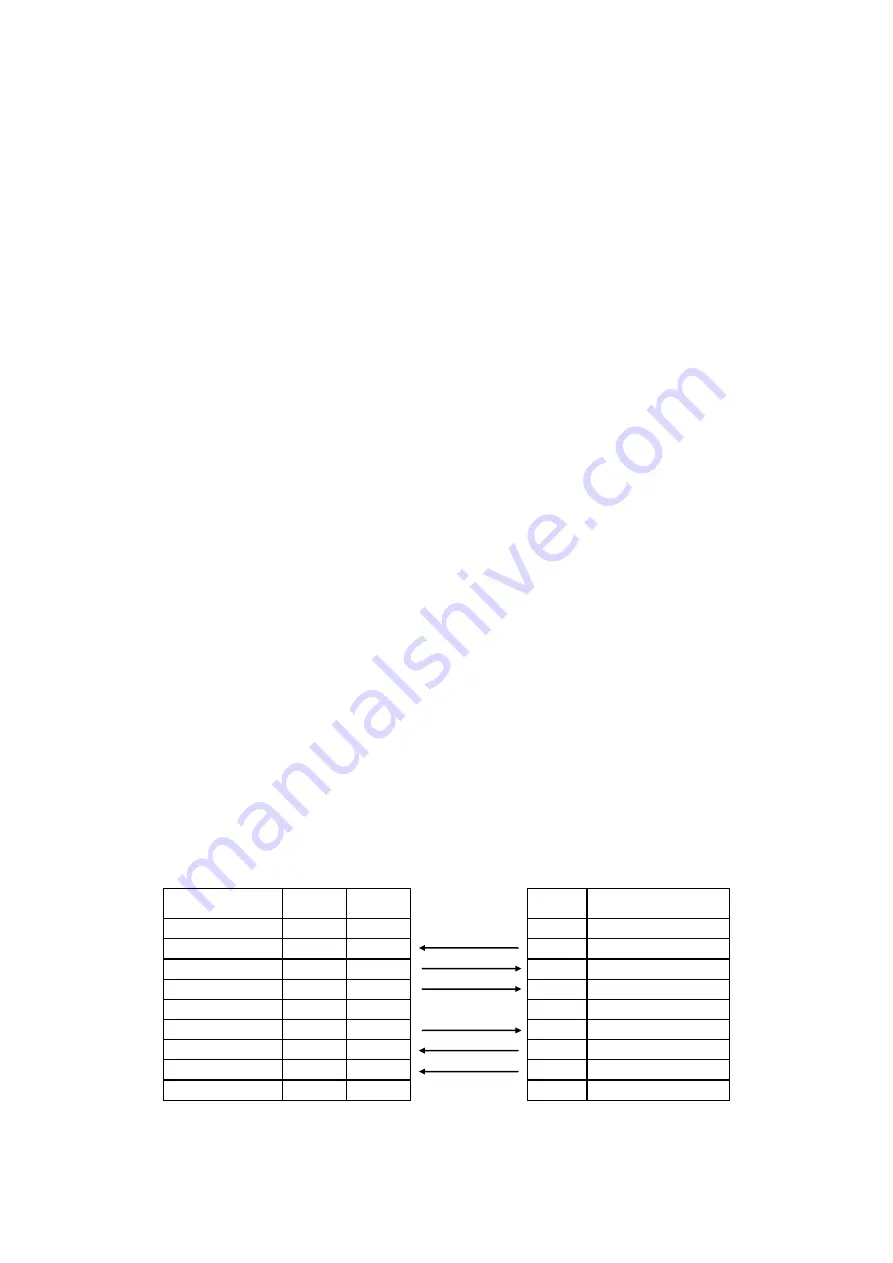

RS-232 Interface Pin Configuration:

Host Function 9 Pin

25 Pin

9 Pin Printer Function

1

+5V

RxD

2

3

2

TxD

TxD

3

2

3

RxD

DTR

4

20

4

DSR

GND

5

7

5

GND

DSR

6

6

6

RDY

RTS

7

4

7

N/C

CTS

8

5

8

RDY

9

+5V