18

Maintenance

E517EN_03.DOC

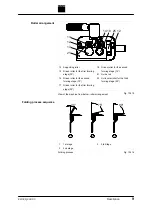

5.1 Tightening screws with turning

moment

14

13

17

22

23

18

13 Roller

(30°)

14 Roller

(75°)

17 Driver roller (30°)

18 Driver roller (75°)

22 Slotted

nut

23 Cylindrical pin 5 m 6x24

DIN 6325

View of the F300 lock seam stripper from below, the

guide rail is dismounted.

If parts of the machine have been disassembled, when

reassembling:

•

tighten screws and nuts with the correct turning moment.

•

secure with Loctite 262.

Components

Torque

Threaded nut retention

Roller (30°)

24 Nm

Loctite 262

Roller (75°)

24 Nm

Loctite 262

Driver roller (30°)

24 Nm

-

Driver roller (75°)

24 Nm

-

Slotted nut

16 Nm

Loctite 262

Cylindrical pin 5 m 6x24

DIN 6325

- -

1

Locking mechanism must be closed (special wrench Material No. 922759).

Fig. 14423

Table 5