Symptom

Probable

Cause

Corrective Action

Recommended Tools

SPEED

FLUCTUATION

S4: Sensor

E5: Speed Sensor

E2: Overspeed

E3: EPROM Error

No Belt Movement

No/Intermittent

Tach Feedback

Overspeed Error

E3: EPROM Error

Software error

during treadmill

startup

•

Go to page

5, 6.

--------

•

Enter Calibration mode

(page 14)

•

Verify speed feedback in speed display

through out the speed range. [Speed

display should never show 0 mph when

belt is moving]

•

If no tach feedback is available perform

speed sensor test

(page 18)

.

•

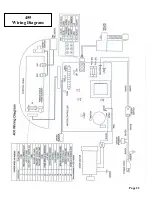

Check continuity of tach feedback

portion of the data cable (To identify

tach feed back lines see wiring diagram

section for specific model).

--------

•

Check/Adjust tread belt tension

(page

20)

•

Perform speed sensor test

(page 18

) If

speed sensor fails adjust gap, if still

fails-replace speed sensor.

•

Perform belt / deck wear test

(page 21)

If badly worn, replace belt and deck.

•

Replace PWM

--------

•

Restart unit- if error persists, replace

control panel.

Multi-meter

Socket Set

Silicone Lubrication

Packet

Silicone Lubrication

Applicator

Note:

All trouble

shooting should

be performed in

calibration

mode.

Page 14

Support Services 800-883-8783

Mon-Fri 8:30am-5:00pm Central Time Zone

Fax: 636-272-7148

Page 11

Содержание 455 Pediatric

Страница 24: ...Page 22 Page 22 455 Wiring Diagram ...

Страница 27: ......