14

4

4

1

44

26

45

11

37

61

7

18*

58

9

12

2

6

5

40

10

39

22

13

161

» Y081564 - (EN - REV. 003) | JUNE 2022

Despite the use of long-life materials, it is necessary to

check some of the components regularly for their general

condition. The following inspection points will ensure a

long-life and trouble-free operation of the disc brake.

Every 3 months

The pad wear must be checked visually and independent of

any wear indicator fitted to the vehicle (see Sections 5.1).

With every pad replacement

It is important to check for the correct functioning of the

adjuster (see Section 5.2) and the smooth operation of the

caliper over its full range of movement (see Section 5.3). Also

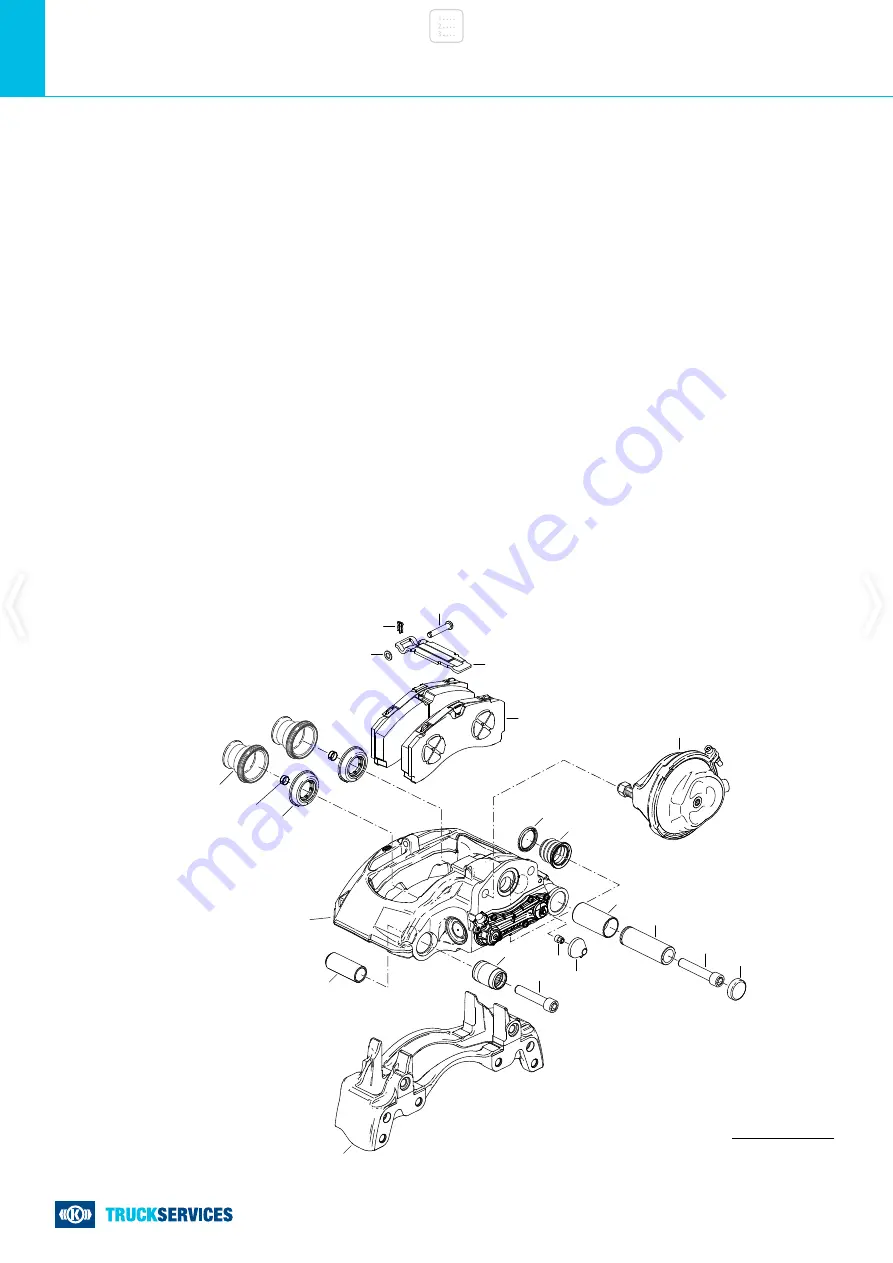

inspect the tappet and boot assemblies (13), the adjuster cap

(37) and the sealing elements (9, 58) for correct fitting and

condition as well as the caliper bearing in the area of the rubber

bush/guide sleeve (6) (see Section 5.3.3).

Annually

Check the caliper running clearance (see Section 5.3.1)

and the correct fitting and condition of the cover (10), the

adjuster cap (37) and cover (68c, 68d or 68e) (depending on

the bearing variant).

Note:

These frequencies are a minimum and, depending

on the vehicle application, a more frequent check of the

components may be necessary.

Refer also to vehicle and/or axle manufacturer’s instructions

in regard to service intervals.

The discs should be checked according to the specification

of the axle or vehicle manufacturer.

In the unlikely event of a problem, all relevant components

must be returned in order that an objective investigation of

the cause can be made.

For further information please refer to the Knorr-Bremse

Dokument Y333409.

*

Variants possible

4. INSPECTION POINTS