EN

8

Operating manual – sabre saw PRCS 10-850

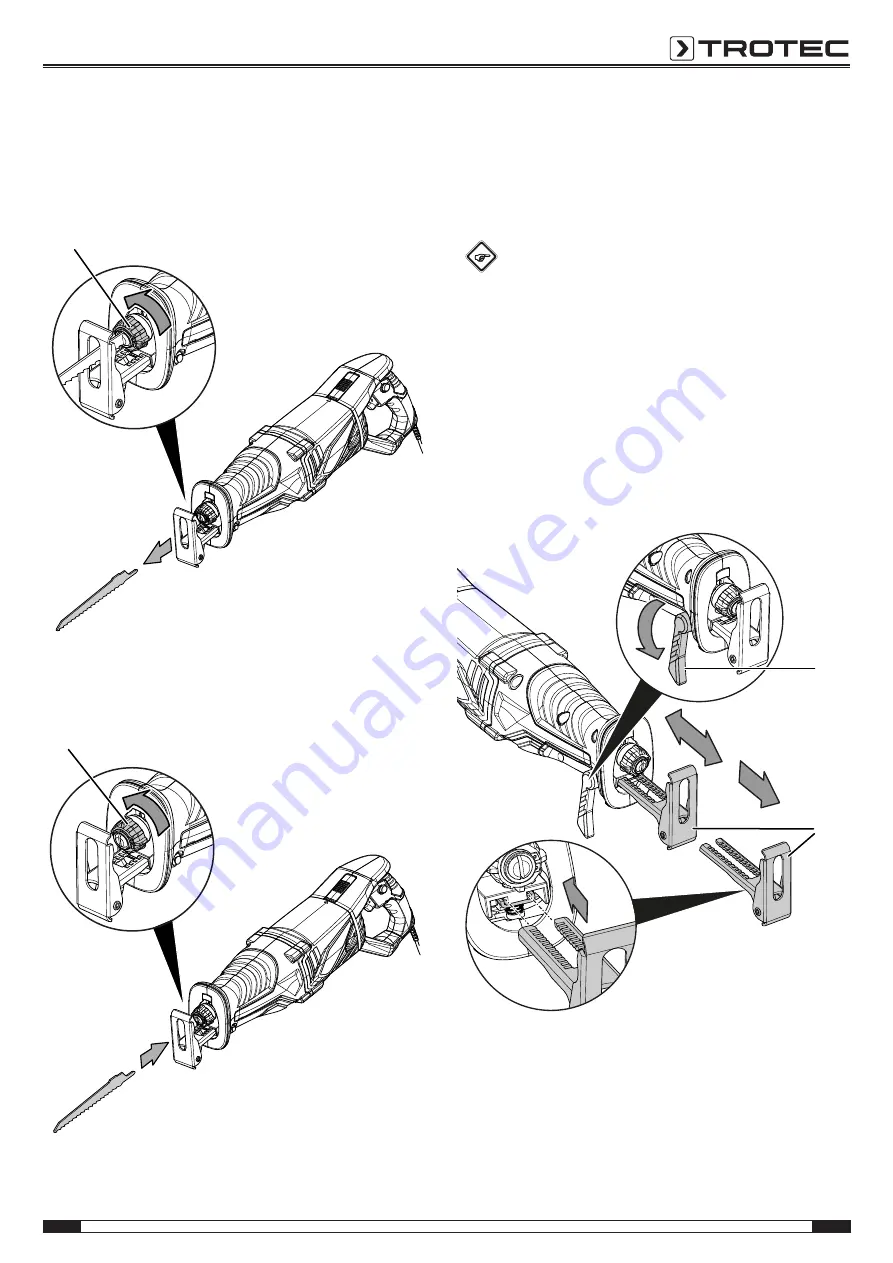

Please proceed as follows to remove or insert a saw blade:

1. Turn the quick-release chuck (11) to the side and hold it in

this position.

If required, you can remove the guide shoe to reach the

quick-release chuck more easily (see Adjusting the guide

shoe).

11

2. If a saw blade is inserted, remove the saw blade from the

quick-release chuck.

3. Insert the saw blade into the quick-release chuck. Make

sure that the teeth of the saw blade point downwards.

11

4. Push the saw blade into the quick-release chuck up to the

stop. Use a suitable saw blade with S-shank or ½''

universal shank.

5. Let go of the quick-release chuck. The quick-release

chuck must return to its initial position.

6. Check whether the saw blade is properly locked in place.

Info

If you turn the handle, the saw blade can be inserted

rotated by 180° (saw blade teeth point in the opposite

direction) to enable easier working.

Adjusting the guide shoe

You can adjust the length of the guide shoe to specify the

plunging depth. Please note that the shoe guide can only be

securely locked up to a certain point. When using a saw blade

that is larger than the recess in the guide shoe, or in order to

facilitate the tool change, the guide shoe can be removed.

1. Release the locking lever (7).

2. Adjust the guide shoe (10) to the desired length. Should

the guide shoe slide out of the guide rail accidentally, it

can simply be reinserted.

7

10

3. Set the locking lever (7) back to its initial position.

4. Check the guide shoe (10) for tight fit.