4

impede stem movement.

7. Be sure that all accessories, brackets, and

bolts are securely fastened.

8. Check rubber bellows for wear.

9. Remove any foreign substances from the

plug system.

10. Spray a soap solution around the cylinder

actuator that retains the ring, adjust screw

and actuator stem guide for air leaks

through the O-rings.

11. If possible, remove air supply and observe

actuator for correct fail-safe action.

12. If the valve contains an air filter, check and

replace cartridge if necessary.

13. Be certain that stem clamp and positioner

linkage are securely fastened. If the stem

clamp is loose, check the plug thread

engagement. (For the correct procedure

on aligning the plug with the seat, refer to

the "Reassembly of the Actuator" section of

this manual).

14. Stroke the valve, if possible, and check for

smooth, full stroke operation. Wobbly stem

movement could be a sign of an internal

valve problem.

Note:

Erratic stem movement is common

whenever Grafoil packing is utilized.

WARNING:

Keep hands, hair,

clothing, etc. away from all

moving parts when operating

the valve.

ASSEMBLY AND DISASSEMBLY

Body Disassembly

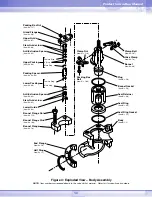

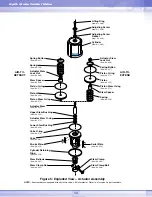

In disassembling the valve body, refer to Figure

4 and continue as follows:

WARNING:

Depressurize line to

atmospheric pressure and

drain all fluids before

commencing work on the valve.

1. If valve is air-to-close, skip to step 2. If

valve is air-to-open, apply air under piston

to raise the plug off the seat before taking

the valve apart.

2. Take out the bonnet flange bolting which

will allow for removal of the actuator,

bonnet, and plug from the valve.

CAUTION:

Heavy actuators may

require a hoist. A lifting ring is

provided on most valves for

this function; otherwise, lift the

valve with the yoke legs using a

lifting strap and a hoist. Care

should be taken to lift the

actuator and plug straight out

of the body to avoid damage to

the seat as well as to the plug.

3. Lift retainer, seat ring, and gaskets from the

body.

4. See to it that the seating surfaces on both

the seat ring and plug are free of damage

so that a tight shutoff is ensured. Be sure

that gasket surfaces on the seat ring,

bonnet, and body are clean and

undamaged.

5. To inspect the plug, remove by loosening

the stem clamp and gland flange, also, take

off the yoke clamps.

Note:

With air-to-close, fail-open valves, it

may be necessary to apply a small amount of

air to the top of the actuator to move the plug

away from the bonnet. If not, some irritation

may occur to the plug.

Turn the actuator off the plug and bonnet

without allowing the plug to rotate inside the

bonnet. Remove the plug carefully through the

packing box.

6. If re-machining is necessary on the seat

surfaces, both surfaces on plug and seat

must be reworked. The seat angle on the

plug is 30 degrees; the seat ring is 33

degrees. Lapping will not be necessary if

proper assembly procedures are followed.

Op

G

L

G

lobe Control Valve