7

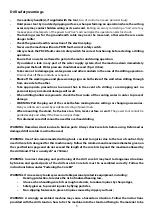

to test. Press the “Reset” button to energize the circuit to the machine.

WARNING! 110V UK machines are not equipped with a PRCD portable residual current device or GFCI

ground fault circuit interrupter. The machine must always be used with an isolating transformer for

protection in case an electrical fault should occur.

WARNING: Always connect the plug into the wall socket with a drip loop. If the cable leads downward

directly into the wall socket, any water on the cable could run into the socket, causing a hazard.

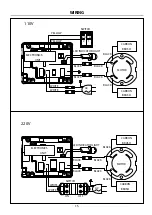

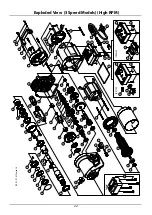

ASSEMBLY

Thread the water supply assy. Into the hole in the bottom of gearbox and tighten with a wrench.

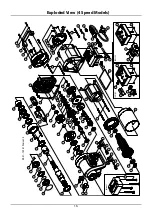

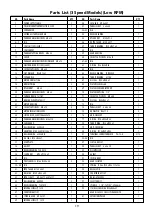

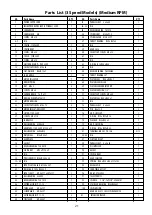

LIST OF CONTENTS

•

Diamond core drilling machine.

•

Mounting spacer

•

Water feed assembly

•

Wrench

OPERATING INSTRUCTIONS

1) MOUNTING THE CORE BIT

CAUTION: Ensure that the threads of the spindle and the core bit match. Attempting to mount

mismatched threads will result in damage to both threads.

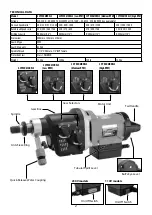

The spindle has two types of threads. The outside male thread is 1-1/4inch UNC, the inside female thread is 1/2

inch BSP. Ensure both the core bit and the machine spindle are clean. Any debris could cause excessive run-out

of the mounted core bit. Excessive run-out can cause premature failure of the core bit and/or a safety hazard.

Tighten the bit to the spindle using two wrenches. Only use correct sized wrenches to avoid damage to the

spindle or bit. Torque to at least 200 newton meters

Choosing the correct core bit for the job:

Ensure that the bit you are using is suitable for the material you are drilling. There are two main types of

diamond core bit:

Wet/dry type-electroplated (surface set) diamond core bits and wet type-sintered (impregnated)

diamond core bits.

We recommend always using wet-type (sintered) bits with this machine.

Electroplated bits, also known as wet/dry type, are only suitable for less hard materials. The diamonds are sharp

and coarse and are only set on the surface. They have a much shorter service life than sintered bits and cannot

be dressed (resharpened). Once they become dull, they must be replaced. They tend to work well with softer,

abrasive materials like brick.