ACC-SVN231A-EN

13

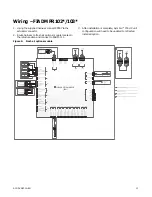

Wiring – FIADMPR102*/103*

1. Using the supplied harness connect PPF87 to the

actuator connector.

2. Route harness to fresh air options module located in

the return section and connect to FAOM-J11.

3. After installation is complete, Symbio™ 700 UC unit

configuration will need to be updated to reflected

installed option.

Figure 9.

Fresh air options module

R

BL

O

R

P

BL

BK

R

BL

BK

R

BL

O

BK R BL

FRESH AIR OPTIONS MODULE

(FOM)

24 VAC OUT

Spare Universal IO 2

Spare Transducer Zeroing Pin

Common

P13

24 VDC OUT

OA Damper Feedback

OA Damper OUT

Common

P10

24 VDC OUT

Spare Universal IO 1

Spare Transducer Zeroing Pin

Common

P12

Return Air Humidity Input

Common

24 VDC OUT

24 VDC OUT

P9

Outdoor Air Humidity Input

Return Air Temp Input

Spare Binary Output 1

Common

P6

Spare Binary Output 2

Common

P7

Spare Binary Output 3

Common

P8

P2

24 V

AC OU

T

RA S

m

oke D

e

tector

Input

Com

m

o

n

P1

P4

GND

Address 3

GND

Address 1

GND

Address 2

Address 4

GND

J11

Spare Univ

ers

a

l Input 5

Com

m

o

n

P14

Cl

ogge

d Fil

te

r Sw

itch IN

24 V

AC OU

T

P15

Spare

B

inary

Inpu

t

3

P16

Spare

B

inary

Inpu

t

4

P17

Spare

B

inary

Inpu

t

5

P18

Spare Analog Output 4

Common

Spare

A

n

alog

O

u

tp

ut

3

Com

m

o

n

P21

Spare

B

inary

Outp

ut

4

P20

24 V

DC OU

T

Spare Univ

ers

a

l Input 7

Spare

U

n

iv

e

rsal

Input 6

J4

Spare

A

n

alog

O

u

tp

ut

2

Com

m

o

n

J5

P19

J6

3

P11

1

2

1

2

J2

3

1

2

J1

1

2

3

4

1

2

3

4

1

2

1

2

3

4

3

4

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

1

2

3

4

3

4

5

6

5

6

1

2

1

2

1

2

1

2

1

2

3

4

3

4

5

6

5

6

7

8

7

8

Modbus

+

Modbus

-

Com

m

o

n

1

2

3

1

2

3

1

2

3

P3

Modbus

+

Modbus -

C

o

mmo

n

1

2

3

24 V

AC OU

T

Com

m

o

n

IMC

+

IMC

-

1

2

3

4

IMC Bus

(White)

P5

White

BK R BL O

24 V

AC OU

T

Com

m

o

n

IMC

+

IMC

-

1

2

3

4

TO UC-P4

SHEET 3

1

2

3

4

Common

Spare Universal IO 1 (Alt)

5 VDC OUT

Common

5 VDC OUT

Spare Universal IO 2 (Alt)

Spare

B

inary

Inpu

t

2

24 V

AC OU

T

24 V

AC OU

T

24 V

AC OU

T

24 V

AC OU

T

Com

m

o

n

Supply

V

o

ltage IN

3

1

2

(Black)

ECA

24 V? IN

DAMPER POSITION IN

DAMPER POSITION OUT

IMC Bus

(White)

(Red)

(Gray)

(Blue)

(White)

(White)

(Black)

(White)

(Purple)

(White)

(Mint)

(Red)

(Pink)

(Orange)

(Green)

(Green)

(Green)

(Blue)

(Yellow)

(Black)

(Black)

(Green)

(Brown)

3

1

2

3

1

2

RASD

24 VAC IN

Smoke Detector OUT

3

1

2

Common

CFS

BK R

BK R

1

2

1

2

1

2

1

1

Common

4 4

BK

O

1

2

1

2

Oponal Return Air Humidity Sensor

-H°

RAH

3

R

Y

1

2

1

2

Oponal Outdoor Air Humidity Sensor

-H°

OAH

4

t°

RAT

BL

BR

1

2

1

2

Oponal Return Air Temp Sensor

2

FRESH AIR OPTIONS MODULE ONLY PRESENT ON CERTAIN UNIT CONFIGURATIONS. SEE INSET A FOR

UNITS WITHOUT FRESH AIR OPTIONS MODULE.

1

BK R BL O

BK R BL O

White

BK R BL O

1

2

3

4

1

2

3

4

White

BK R BL O

1

2

3

4

TO IOM-P4

SHEET 5

1

2

3

4

TO AIRFI

1

INSET A

BK R

BK R

XFR

2

1

White

BK R BL O

1

2

3

4

TO AIRFI

3

4

2

RETURN AIR TEMP SENSOR PRESENT ON UNITS WITH DIFFERENTIAL DRY BULB, REFERENCE ENTHALPY,

AND COMPARATIVE ENTHALPY CONTROL

RETURN AIR HUMIDITY SENSOR PRESENT ON UNITS WITH REFERENCE ENTHALPY AND COMPARATIVE

ENTHALPY CONTROL

RETURN AIR HUMIDITY SENSOR PRESENT ON UNITS WITH COMPARATIVE ENTHALPY CONTROL

PPF62

PPF63

PPF64

PPF87

PPM87

PPF88

PPM88

PPF86

PPM86

BK

2

1

TO LINE 320

Sheet 6

J11-1

TO LINE 322

Sheet 6

J8-1

3

1

2

ECA

24 V? IN

DAMPER POSITION IN

DAMPER POSITION OUT

Common

4

BK

R

BL

O

3

1

2

4

Oponal Horizontal Low Leak

Oponal Economizer

Oponal Economizer

Oponal Return Air Smoke Detector

Oponal Power Exhaust

Содержание Precedent FIADMPR102 Series

Страница 14: ...Notes 14 ACC SVN231A EN...

Страница 15: ...Notes ACC SVN231A EN 15...