Installation

14

CLCH-SVX08C-EN

•

For VAV units, provide temperature sensors for

entering and leaving air in gas heat section.

Note:

All power and control wiring for the gas heat

section must be field-provided. All power and

control wiring for any section downstream of the

gas heat must be field-provided.

Lifting and Rigging

Refer to

CLCH-SVX07*-EN Performance Climate

Changer™ Air Handler Installation, Operation, and

Maintenance

manual for instructions on equipment

rigging and lifting. This manual ships inside the unit fan

section.

Placement and Assembly

Refer to the design engineer’s plans and submittals for the

location of the gas heat section in the air handler. The gas

heat section will arrive at the job site as an individual

section. It is not shipped with the air handler.

Hardware for fastening the gas heat section to the air

handler can be found in the unit fan section.

Final assembly of the air handler should be done at the unit

installation site. Refer to

CLCH-SVX07*-EN Performance

Climate Changer™ Air Handler Installation, Operation,

and Maintenance

manual for instructions on equipment

assembly.

Flue Stack for Outdoor Air Handlers

The flue stack for outdoor air handlers must be mounted

on the flue opening on the side of the unit. The flue stack

must be installed on the gas heat section

before

assembling the gas heat section to the air handler. It is very

difficult to remove the flue from inside the unit once the

unit is assembled.

Installation

High Altitude Installations

Adjustment of gas train linkages is not normally required.

However, for high altitude installations, adjustment to the

air-fuel linkages may be necessary for proper combustion.

Heater outputs must be derated four percent for every

1000 feet over 2000 feet above sea level. When specifying

gas heaters, the engineer should provide the MBh and

airflow required at altitude. All Trane literature is based on

nominal outputs at sea level.

It is recommended that the services of an experienced,

qualified gas heat technician be employed to adjust air-fuel

linkages for proper combustion.

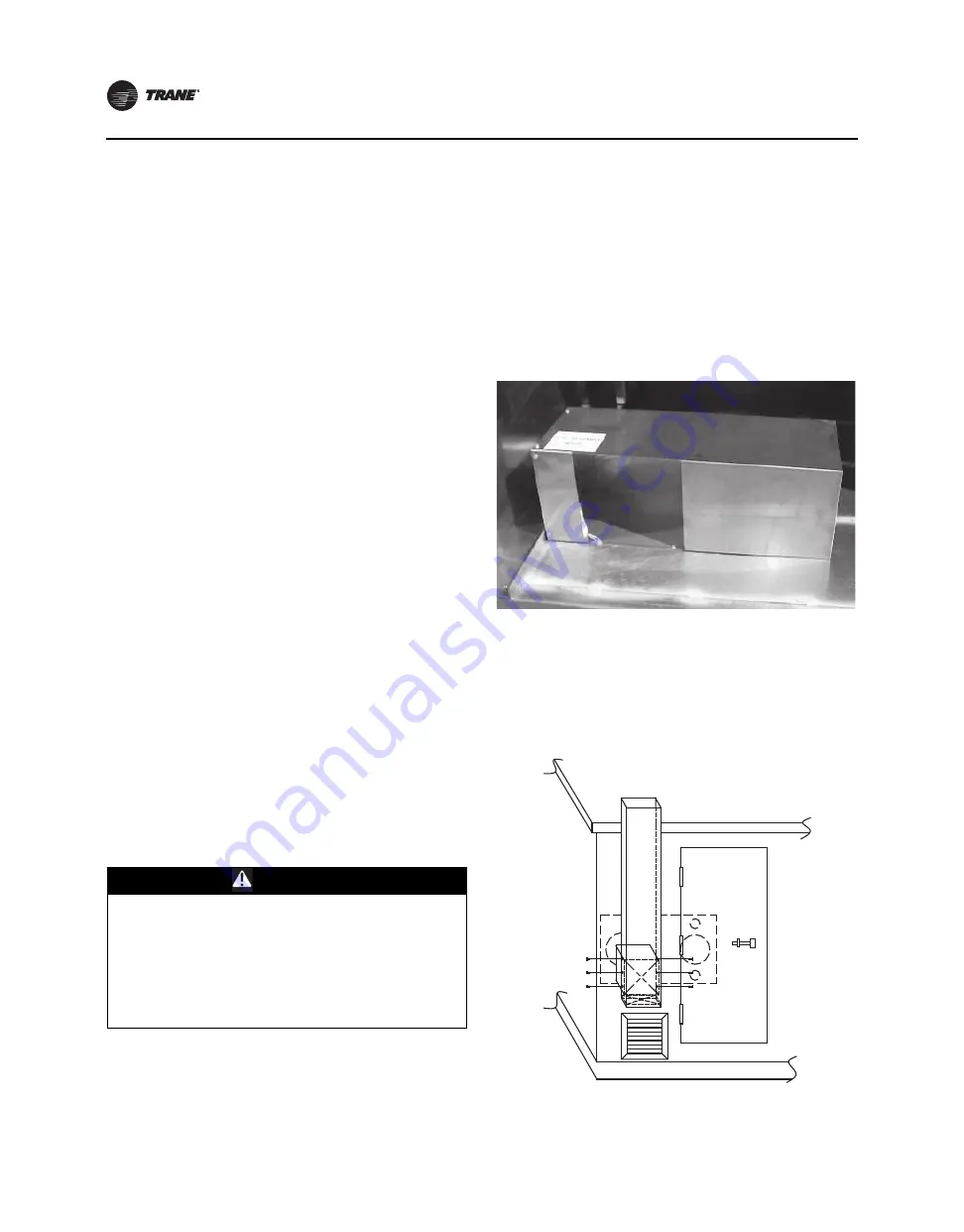

Installing Outdoor Flue Stacks

The flue stack for outdoor gas heat sections ships inside

the gas heat section or in one of the other sections of the

air handler.

Attach the flue stack to the flue collar and secure it with

screws as indicated in

.

A field-provided rain hood or screen is recommended on

the flue to prevent possible blockage from bird nests and

beehives.

shows flue connection sizes for the gas heat

section.

WARNING

Hazard of Explosion!

Installations at altitudes of 3,000 feet above sea level or

higher may require adjustment of the air-fuel linkage

for proper combustion. Linkage and air-fuel adjustment

should only be done by an experienced, qualified gas

heat technician. Failure to follow these

recommendations could result in death or serious

injury or equipment or property-only damage.

Figure 5.

Outdoor air handler flue stack

Figure 6.

Outdoor air handler flue stack installation

Содержание K01K12345

Страница 21: ...Wiring CLCH SVX08C EN 21 Figure 16 Natural gas 200 320 MBh 10 1 turndown...

Страница 22: ...Wiring 22 CLCH SVX08C EN Figure 17 Natural gas 360 1000 MBh 3 1 and 10 1 turndown and propane 200 1000 MBh...

Страница 23: ...Wiring CLCH SVX08C EN 23 Figure 18 Single phase natural gas and propane 1250 2000 MBh 3 1 and 10 1 turndown...

Страница 25: ...Wiring CLCH SVX08C EN 25 Figure 20 Natural gas and propane1250 2400 MBh 20 1 turndown...

Страница 34: ......

Страница 35: ......