18-AC80D1-2

5

Installer’s Guide

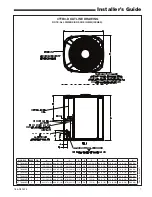

TyPICAl FIelD hOOkUP DIAGrAMS

Notes:

1. Be sure power supply agrees with equipment nameplate.

2. Power wiring and grounding of equipment must comply with local codes.

3. Low voltage wiring to be No. 18 AWG minimum conductor.

4. ODT-B must be set lower than ODT-A.

5. If outdoor thermostats (ODT) are not used, connect W1 to W2 and W3.

leGenD

FACTORY WIRING

FIELD WIRING

PRINTED FROM B152901 P02

PRINTED FROM B152903 P02

NOTE

*

*

W2 present only on 2 stage

thermostat and furnace