18-GE15D1-2

9

Installer’s Guide

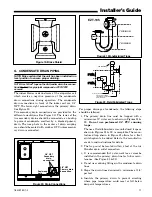

Rail

Figure 16. Mounting Installation Options

for Horizontal Applications

HORIZONTAL RIGHT

1.

Unit is shipped from the factory in the horizontal

right configuration. Unit conversion is not re-

quired.

2.

If the unit is suspended, it must be supported

from the bottom near both ends as well as the

middle to prevent sagging. The service access

must remain unobstructed. If the unit is sup-

ported along the length of the front and back

with rails, the air handler only needs to be sus-

pended at both ends. See Figure 16.

3.

If the unit is not suspended it must be supported

as mentioned above and isolated carefully to pre-

vent sound transmission. Vibration isolators (field

supplied) must be placed under the unit.

4.

It is always recommended that an auxiliary drain

pan be installed under a horizontal Air Handler

(See Condensate Drain Piping) to prevent pos-

sible damage to ceilings.

5.

Isolate the auxiliary drain pan from the unit or

from the structure.

6.

Connect the auxiliary drain line to a separate

drain line (no trap is needed in this line) and ter-

minate according to local codes.

7.

If a return duct is connected to the air handler, it

must be the same dimensions as the return

opening shown in Figure 17 and the outline

drawing on page 21.

8.

Openings where field wiring enters the

cabinet must be completely sealed.

Location

of power entry is shown on the outline drawing.

Use 2.5" clear stickers to seal all unused electri-

cal knockouts. See Figure 13.

9.

After ductwork connections are made, seal air-

tight and per local codes.